One of the core elements of society today, steel is utilized in many areas of our daily life as one of the most essential building elements. One of the three largest carbon dioxide producers at the moment is the steel sector. In order to decrease their carbon footprint from both an environmental and an economic perspective, steel players around the world are increasingly faced with a decarbonization problem. Within the next 10 to 20 years, we must take significant measures to achieve net-zero carbon emissions if we hope to keep global warming to 1.5 to 2 degrees.

In terms of energy consumption, the iron and steel industry is currently the largest industrial sector. The creation and deployment of cutting-edge, energy-efficient technology are therefore crucial for the production of steel. Investment to totally change from BF to EAF would take time, therefore, there are multiple ways to support this process of global decarbonization contribution.

Let's introduce to you various methods and ways in this blog post to know different ways to decarbonize the steel industry.

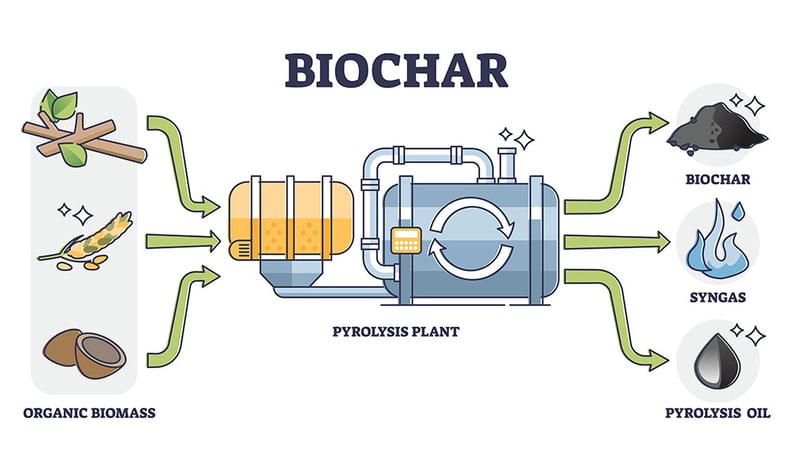

Syngas

The primary use of syngas, which is often a coal gasification byproduct, is the production of electricity. It is possible that using the syngas will be more effective than burning the original fuel directly. To produce a high-quality reducing gas for steel production, syngas may be used.

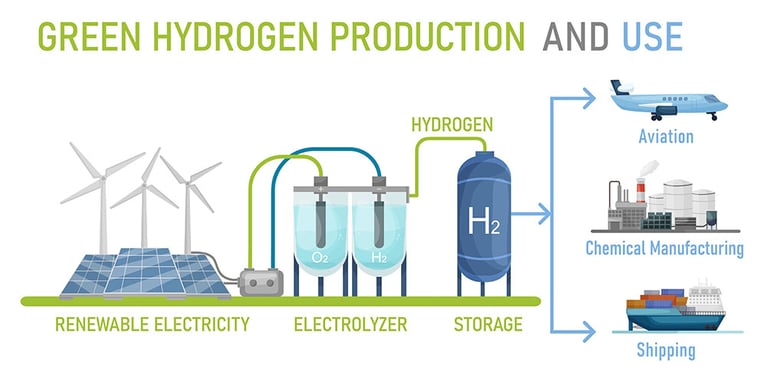

Hydrogen & Solar Power

We can become independent and lessen our reliance on imported coking and non-coking coal by producing steel using green hydrogen. Any current investment in blast furnaces will guarantee a requirement for imported coal into the mid-century and beyond. The sector might be substantially decarbonized if hydrogen produced from renewable energy (Green Hydrogen) took the place of coal. The cost of steel would increase if hydrogen took the place of coal at the current pricing levels.

The temperatures required for traditional steel products are produced using a significant quantity of fossil fuel energy. The energy produced by fossil fuels can be substituted by energy produced by solar power in steel plants. The fact that solar electricity is now the cheapest form of energy in many developing countries is an additional benefit.

Daiwa Lance makes lance pipes as materials that could contribute producing solar panels around the world, especially Europe area. An aluminum lance pipe is a pipe used in smelting silicon metal as an initial step to producing solar panels. Silicon metal is the main material for producing solar panels.

Recycling Steel Scrap

Recycling steel lowers the amount of ore that must be mined, conserves energy, and minimizes greenhouse gas emissions. Steel may be recycled indefinitely without losing any of its original characteristics. By doing this, a non-renewable resource becomes one. There are fewer carbon emissions since steel recycling utilizes about half the energy of basic steel manufacturing.

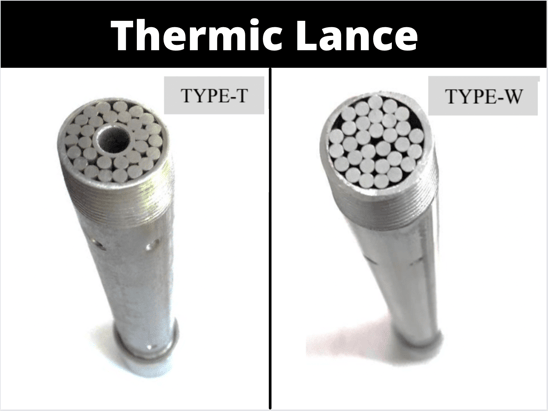

We also have Thermic Lance (TL), which is used to cut steel scraps used as main materials for EAF. Thermic Lance is a steel pipe filled with inner tubes and wires and creates a super high temperature and powerful flame by burning itself and producing high heat, and can produce a super high heat rate up to 4,000℃.

If you wish to know more about lance could be suitable with your purpose on how to decarbonize during steel production process, contact our dynamic team to get more precise information. We will support you during your production journey with the best performance.

- Category:

- General Topics

- Keyword:

- SDGs

- Oxygen Lance

- Thermic Lance