In the metalmaking industry, where labor, expertise, and machinery skills are paramount, oxygen lance pipes, particularly Calorized Lance Pipes are highly important products. But what happens when this crucial tool is rapidly consumed due to the intense heat and high temperatures from the furnaces? This dilemma presents a significant challenge for plant managers. In this article, we will explore in depth the reasons behind the quick consumption of unqualified Calorized Lance Pipes, offering insights to enhance your understanding of this essential product.

Quick Consumption Problem

When used in a metal melting furnace that operates at scorching temperatures of up to 1,600°C, Calorized Lance Pipes will quickly interact with the large quantity of scrap material being introduced into the furnace. For Calorized Lance Pipes that fail to meet the necessary standards, the issue of them being rapidly consumed by the molten metal will inevitably arise.

Negative Consequences of Quick Consumption

Unexpected quick consumption is a problem that no plant managers or factory workers want due to the disruptions it causes. The negative consequences of such quick consumption include:

- Increased production costs due to the high quantity of unqualified Calorized Lance Pipes required for metal melting.

- Disrupted and non-continuous operations as unqualified Calorized Lance Pipes are consumed too quickly.

- Prolonged metal melting time when qualified Calorized Lance Pipes are continuously consumed.

- Difficulty for operators who must constantly replace consumed Calorized Lance Pipes.

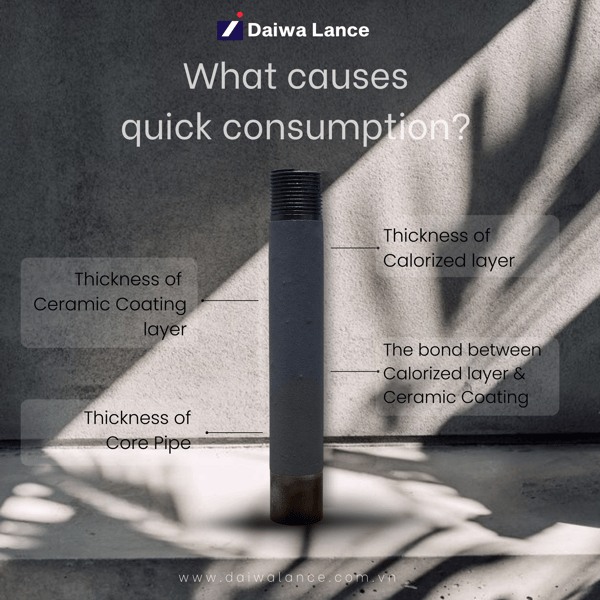

What Causes Quick Consumption?

Now that we have identified the negative results of quick consumption caused by unqualified Calorized Lance Pipes. It is crucial to further understand the underlying factors that directly impact the speed at which these pipes are consumed. In simpler terms, there are three key factors that contribute to the quick consumption of unqualified Calorized Lance Pipes.

- Thickness of calorized layer: If the calorized layer is too thin, its heat resistance is compromised, leading to quick consumption. An appropriate thickness for the calorized layer will be a better choice to ensure optimal consumption rate during a tap-to-tap cycle.

- Thickness of ceramic coating layer: A thicker ceramic coating layer will provide better protection against the intense heat from the furnace.

- Thickness of core pipe: A thicker core pipe results in slower consumption. For example, using a 2.5mm thickness instead of 2.3mm enhances heat resistance and reduces the consumption rate of Calorized Lance Pipes.

- The bond between calorized layer and ceramic coating: If the bond between calorized layer and ceramic coating is weak, ceramic coating may peel off from the surface of Calorized Lance Pipe. This can lead to a failure in protecting the pipe, ultimately making quick consumption more likely to occur.

However, increasing the thickness of these layers still has a side effect such as brittle characteristics and weight, affecting the overall quality, cost and ease of operation.

Next, allow us to introduce you to what we consider the a top-tier high-quality Calorized Lance Pipe.

What Should a Good Quality Calorized Lance Pipe Be Like?

A good-quality Calorized Lance Pipe that can address the issue of quick consumption should possess the following key features.

- Appropriate thickness: the thickness of the calorized layer, ceramic coating layer, and core pipe needs to be designed well in order that Calorized Lance Pipe are not quickly consumed in the molten metal while also meeting the requirements of the customers.

- Appropriate weight: A good-quality Calorized Lance Pipe is characterized by having the right weight - not too heavy, which helps in cutting costs and minimizing operator fatigue during metalmaking operations..

Daiwa Lance's Improvement Methods

In Daiwa Lance, to improve the performance of Calorized Lance Pipe for plant managers, production team leaders, and individual workers, we implement below improvements on a regular basis.

- We ensure stable alloy composition in calorized and ceramic coating layers as committed.

- We maintain and continuously improve the quality management system.

- We offer flexible solutions to address customer challenges, always listening and developing products, sizes, weights, and corresponding accessories.

- We diversify products to meet the specific needs of each customer.

Conclusion

Every problem will not be solved in a single attempt, so what we need is time, information, and consultation from experts or reliable Calorized Lance Pipe suppliers.

Having grasped the underlying factors that significantly impact the quick consumption of Calorized Lance Pipes, the next step is to pinpoint the specific areas that need improvement.

If you require assistance with the quick consumption issue in your factory, feel free to reach out to Daiwa Lance by clicking the link provided. Rest assured, we are committed to addressing all inquiries promptly within a span of 24 hours.

- Category:

- Daiwa Lance Products