"Is Daiwa Thermic Lance compatible with our automotive lancing equipment?"

"Can Daiwa Thermic Lance effectively cut through round profiles?"

"Are you confident that Daiwa Thermic Lance can effectively handle the materials we need to cut?"

If you've ever pondered these questions, take a moment to read the article below for some insightful answers.

.png?width=500&height=500&name=Thermic%20Lance%20Applications%20(By%20Usage).png)

Basically, Daiwa Thermic Lance is an energy-saving powerful cutting and burning tool with high velocity of oxygen pressure that can generate a high temperature up to 4,000oC. Therefore, any applications that align with this capability are suitable.

Whether your goal is to slice through a circular profile, tackle reinforced concrete, or dispose of steel scraps, rest assured that Daiwa Thermic Lance is up to the challenge.

Listed below are some recommended uses for the Daiwa Thermic Lance, showcasing its exceptional cutting and burning capabilities.

Cut Hard Materials

This is the primary purpose when using Daiwa Thermic Lance.

The steel wires inserted within Daiwa Thermic Lance enhance the combustion process to unparalleled levels. This is what empowers Daiwa Thermic Lance to effortlessly melt and cut hard materials like stainless steels, refractory concretes, fire bricks, natural stones, or steel pipes of the embankment construction.

RELATED POST

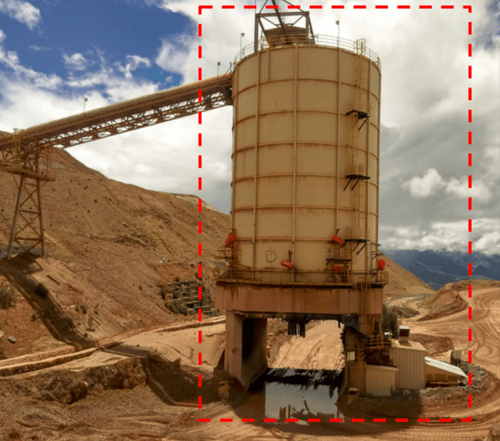

Demolish Buildings

Instead of relying on heavy excavators for the demolition of structures like high-rise skyscrapers or ore bins in mining closures, you can consider the versatile alternative of using Daiwa Thermic Lance.

By eliminating the need to handle heavy machinery, operators can work with more precision and less fatigue.

Remove Slags in Steel Mills

Slag, known for its abrasive nature, poses a threat to equipment like conveyor belts and machinery in steel mills, leading to escalated maintenance costs and operational downtime. With a melting point of 1,780oC, removing solidified slags using a low melting temperature cutting and burning tool proves to be quite challenging.

With the use of Daiwa Thermic Lance, we can confidently handle any stubborn solidified slags that may be lingering in plant decks, working floors, ladle furnaces, mixer cars, or casting equipment, ensuring a thorough and efficient cleanup process.

Scrap Cutting in Scrapyards

Every day, the metal manufacturing process releases significant amounts of scrap metal into the environment, much of which is recyclable. With its specialized cutting and burning capabilities, Daiwa Thermic Lance can efficiently break down scrap metals of all sizes - whether large, medium, or small - without any issues of oxygen leakage, thanks to the robust design made by Daiwa Lance.

Tap Hole Opening in Furnaces

The high velocity of oxygen and strong flame that flows inside the hollow pipes of Daiwa Thermic Lance greatly contributes to the use of tap hole opening.

By maintaining its intense flame even after ignition, the Daiwa Thermic Lance aids operators in efficiently opening tap holes with high oxygen pressure in furnaces, ultimately saving time and effort in the process.

Conclusion

Given the suggested applications mentioned above, we believe that you can visualize how Daiwa Thermic Lance can be applied to meet your specific requirements in cutting and burning. For additional details such as Daiwa Thermic Lance's sizes, structure, delivery time, or warranty policies, please click the link below to contact us.

- Category:

- Daiwa Lance Products

- Keyword:

- introduction to thermic lance