Lance pipe end-users have alternative options for using steel pipes to enhance efficiency depending on the application and usage objectives, especially for oxygen lancing purposes. Today, we'll introduce to you the information on 3 main types of steel pipe used in the steel melting and refining industry, including Mild Steel pipe, Ceramic Coated Lance pipe, and Calorized Lance pipe.

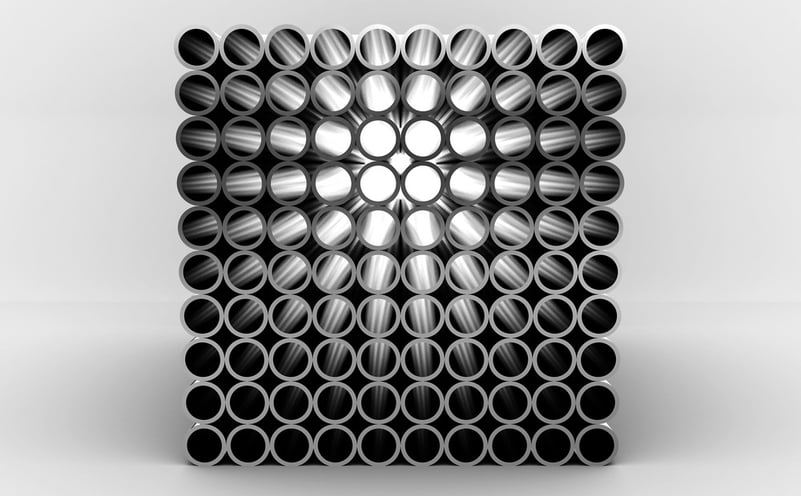

What is Mild Steel Pipe?

Mild steel (MS) pipes are made of steel with a low carbon content (less than 0.25 %). The pipes do not harden and are easy to use because of their low carbon content. MS Pipes are readily welded and molded into various forms and sizes for pipelining and tubing applications since they are constructed of mild steel. This kind is commonly applied in a variety of industrial and engineering applications, as well as for lancing purposes in steel manufacturing.

- Photo of Mild Steel Pipe:

RELATED POST

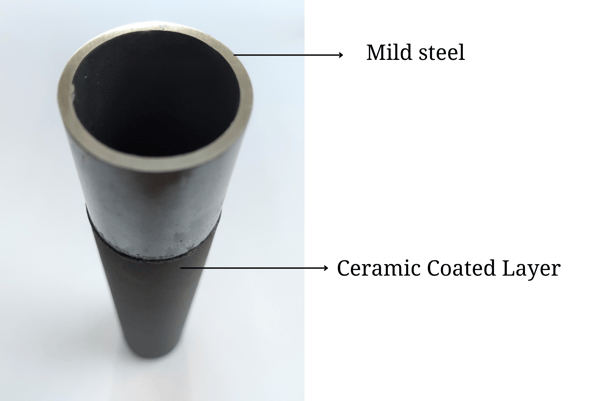

What is Ceramic Coated Lance pipe?

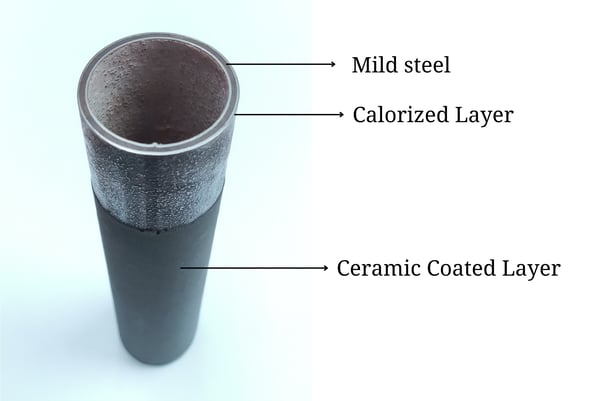

Ceramic Coated Lance Pipes (CC Lance Pipe) is manufactured by applying a special refractory coating on the inside and outside of mild steel pipe. Depending upon the normal bore of the pipe refractory coats are applied both inside and outside of the pipe. This improves the resistance of the Ceramic Coated Pipes to the attack of liquid metal and slag. It is used in Electric Arc Furnace for oxygen, and other gas blowing. The Coating Layers are provided in more than 1-time coating layer, depending on each customer's requirement. Compared to Calorized Lance pipe, Ceramic Coated Lance pipe is easier to burn during usage.

-

Photo of Ceramic Coated Lance pipe:

What is Calorized Lance pipe?

DAIWA CA LANCE (CA Lance pipe) is produced by our know-how of Calorizing process technology. During the production, Calorized layer and Ceramic coating are provided both for the outside and inside of the pipe. Our calorizing process lets CA Lance pipe stand for a much longer time than normal Mild steel pipe. It is used for oxygen/carbon injection for steel making. The calorized layer and the refractory coating layer together generate strong heat resistance and anti-oxidation to achieve minimum consumption of lance pipe to cut down your cost.

- Photo of Calorized Lance Pipe

Comparison Chart

The table below is a comparison of 3 Steel Pipes in the steel manufacturing industry for Lancing purposes Application. We will compare the 3 types of pipes based on the factors such as Applications, Harness / Toughness, Heat Resistance Performance. You can see the remarkable performance result by our Daiwa Lance internal testing, especially CA Lance pipe, due to applying Daiwa Lance technology in Calorizing process production.

|

Type |

MS pipe |

CC Lance pipe |

CA Lance pipe |

|

Applications

|

|

|

|

|

Hardness / Toughness |

Normal |

Good |

Excellent |

|

Heat Resistance Performance (Internal Testing Result - under Oxygen Acetylene Torch Flame at 3000oC) |

20 seconds |

47 seconds |

151 seconds |

* The performance results will be different, depending on usage conditions.

Conclusion

Depending on each application and usage purposes, end-users have many options to use steel pipes to enhance the performance. For steel melting and manufacturing, Daiwa Lance has our own Calorizing process that can provide both Calorized Lance Pipe and Ceramic coating Pipe with the intention to make it stand for a much longer time than Mild steel pipe. And this is why Calorized Lance becomes a good option for oxygen or carbon injection in the steelmaking process.

- Category:

- General Topics