Working in the steel refining furnace amid the intense temperatures exceeding 1,600oC presents a challenging challenge. Apart from enduring the scorching heat, workers must also face the challenge of working under the scorching heat with time constraints to ensure top-notch quality in the final product. Hence, tools that enhance the oxygen blowing rate are important in melting metal with superior heat resistance, ultimately reducing fatigue and mitigating occupational hazards for the workforce. For a more in-depth look at how the calorized layer in the Calorized Lance Pipe enhances heat resistance, take a look into the article below.

What is Calorized Layer?

The calorized layer on Calorized Lance Pipe is an indispensable component that contributes to the outstanding characteristics of this product. Simply put, the calorized layer is an aluminum-iron alloy layer created through the vaporization process of aluminum, permeating the surface of the steel at temperatures above 1,000oC.

During the process of blowing oxygen into the Electric Arc Furnace (EAF), the calorized layer acts as a heat-resistant barrier, preventing direct contact of Calorized Lance Pipe with the molten metal boiling in the furnace at high temperatures.

Thanks to the excellent heat resistance of this calorized layer, the pipe's lifespan is extended, and the necessary time for workers to replace the Calorized Lance Pipe is minimized.

RELATED POST

How does Calorization Process Occur?

The calorization process involves several stages. Firstly, aluminum needs to be vaporized at an appropriate temperature, above 1,000oC. Then, the steel will be melted, mixing with the vaporized aluminum to create a high-adhesion aluminum-iron alloy layer on the surface of the Calorized Lance Pipe.

In theory, the calorization process follows a certain procedure, but to achieve a truly high-heat-resistant calorized layer, crucial factors such as the mixture ratio of calorized powder, the necessary temperature for vaporizing aluminum, and the time for calorizing the aluminum-iron alloy must be carefully calculated.

Once coated with the calorized layer, the lifespan of Calorized Lance Pipe sees a remarkable increase of approximately 3 to 10 times compared to standard steel pipes typically found in the market. This enhancement serves as a vital and standout benefit of Calorized Lance Pipe, showcasing its exceptional heat-resistant qualities.

.png?width=600&height=600&name=Extended%20Lifespan%20-%20Calorized%20Lance%20Pipe%20(x7).png)

The Current Situation of Oxygen Blowing Pipes Usage

Due to the complexity of Calorized Lance Pipe production technology and the need for precision in balancing the mixture ratio of the aluminum-iron alloy, many companies cannot produce the calorized layer.

Instead, opting for standard black pipes or occasionally adding a ceramic coating layer to steel pipes for oxygen blowing in steel refining furnaces may seem like an easier choice. However, while these alternatives may come at a lower cost compared to Calorized Lance Pipe, they often result in trade-offs in quality, lifespan, and the frequency of pipe replacement.

By selecting Calorized Lance Pipe with its specialized calorized layer designed for high-temperature environments, we can ensure unmatched performance and durability, outshining traditional options.

).png?width=600&height=600&name=Daiwa%20Calorized%20Lance%20Pipe%20(3~10%20expanded%20strength)).png)

So, What Happens When Using Oxygen Blowing Pipes Without The Calorized Layer?

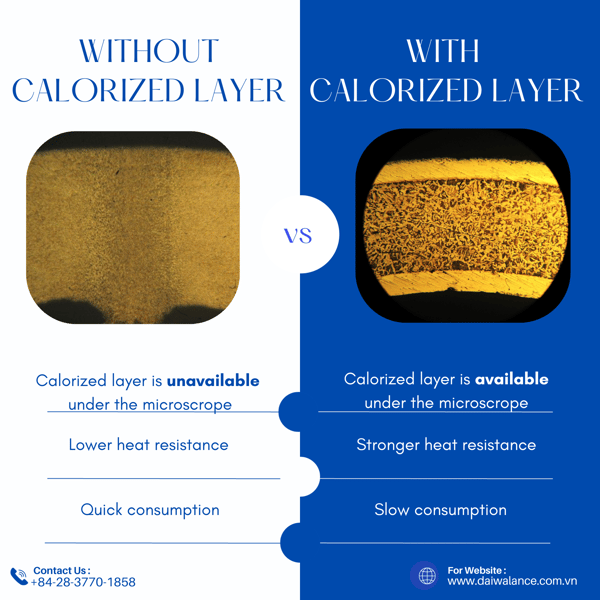

Firstly, we need to understand two important characteristics of the calorized layer:

- Enhanced heat resistance.

- High hardness.

Heat resistance helps extend the lifespan of the pipe, minimizing the need for replacement. High hardness ensures that the pipe remains straight and does not deform when exposed to temperatures above 1,600oC from the melting furnace.

Below is a microscopic view that illustrates the difference between a calorized pipe and a non-calorized pipe.

For Daiwa Lance's Calorized Lance Pipe product, the calorized layer is diffused and permeates both the outer and inner surfaces of the Calorized Lance Pipe, creating a high-adhesion barrier for the pipe.

Visually, the calorized layer appears silver in color to the naked eye. However, when observed under a microscope, the calorized layer is coated on the inside and outside of the steel pipe. If any Calorized Lance Pipe product does not reveal the calorized layer under the microscope, it indicates that the pipe has not truly undergone the calorization process, and its performance and durability during the oxygen blowing process will be negatively affected.

Conclusion

Upon closer examination of the importance of the calorized layer, it becomes clear that selecting a supplier of Calorized Lance Pipe with a high-quality calorized layer is paramount. A quality calorized layer plays a crucial role in shielding the steel pipe from extreme temperatures in the steel refining furnace, reducing fire corrosion, prolonging lifespan, minimizing the need for frequent pipe replacements, and easing the strain and fatigue on workers. If you have any further inquiries or wish to explore further into finding a trustworthy Calorized Lance Pipe supplier, feel free to reach out to Daiwa Lance for more information.

- Category:

- Daiwa Lance Products