Daiwa lance is an oxygen lance pipe manufacturer with various ranges of OD. Compared to the usual situation, there is a range of bigger oxygen lance pipes with larger 2-1/2" O.D. Especially, the demand is coming from Trash Burning Furnaces and Electric Arc Furnaces (EAF) which are looking for good-performance oxygen lance pipes at reasonable prices. Currently, the 2-1/2" O.D. lance pipe is not normally used and has not been manufactured. In the meantime, there is currently a demand for 2-1/2" OD oxygen lance pipes from newly constructed clean centers, but there are few manufacturers that can supply such products. The trend toward larger size electric furnaces is creating a need for larger diameter lance pipes to allow sufficient oxygen to be blown into the furnace during the reduced heating operation time.

Daiwa lance is an oxygen lance pipe manufacturer with various ranges of OD. Compared to the usual situation, there is a range of bigger oxygen lance pipes with larger 2-1/2" O.D. Especially, the demand is coming from Trash Burning Furnaces and Electric Arc Furnaces (EAF) which are looking for good-performance oxygen lance pipes at reasonable prices. Currently, the 2-1/2" O.D. lance pipe is not normally used and has not been manufactured. In the meantime, there is currently a demand for 2-1/2" OD oxygen lance pipes from newly constructed clean centers, but there are few manufacturers that can supply such products. The trend toward larger size electric furnaces is creating a need for larger diameter lance pipes to allow sufficient oxygen to be blown into the furnace during the reduced heating operation time.In this blog post, we would like to offer to introduce our flexibility to manufacture oxygen lance pipe designs and sizes according to customer demand, which is one of many good ways to inject oxygen used for Electric Furnace and Trash burning furnaces (Incinerators).

Trash Burning Furnace (Incinerator)

An incinerator, also known as a trash-burning furnace, is a furnace used to burn rubbish. Equipment to reduce pollutants, including flue gas cleaning, is included in modern incinerators. An oxygenated single combustion chamber is used to burn waste. Extremely high temperatures cause materials to burn. Waste should totally combust at those temperatures, producing only gases and ash as a by product.

Photo of one part of the Incinerator

Requirement of Oxygen to Performance of Trash Burning Furnaces and Electric Arc Furnaces

- For Trash Burning Furnaces: A fuel and oxygen undergo a speedy, exothermic reaction known as combustion (O2). Although fossil fuels may also be used in conjunction with trash as fuel in incineration applications, the air is the primary oxygen source. Incineration temperature, gas mixture turbulence, and gas-residence time must all be taken into account for a furnace to be designed and operated in the best possible way. A sufficient amount of fuel and oxygen must be supplied, and every component of the gas stream must attain an appropriate high temperature for a sufficient amount of time.

- For Electric Arc Furnace: Intense heat is produced for cutting the scrap when oxygen combines with the hot scrap and burns the iron. After the steel has started to melt, oxygen can be injected right into the steel bath. In Electric Arc Furnaces, the typical oxygen consumption rises every year. The average specific consumption is rising in line with the present trend. Steelmakers are discovering that by utilizing more oxygen in their operations, they can still boost output and make money. As a result, techniques for infusing chemical energy into the EAF have recently advanced.

The requirement for higher consumption of oxygen used for that furnace is increasing which lead to the increase in demand for larger oxygen lance pipe to inject more oxygen and improve the performance process.

Oxygen Lance Pipes for TBS and EAF

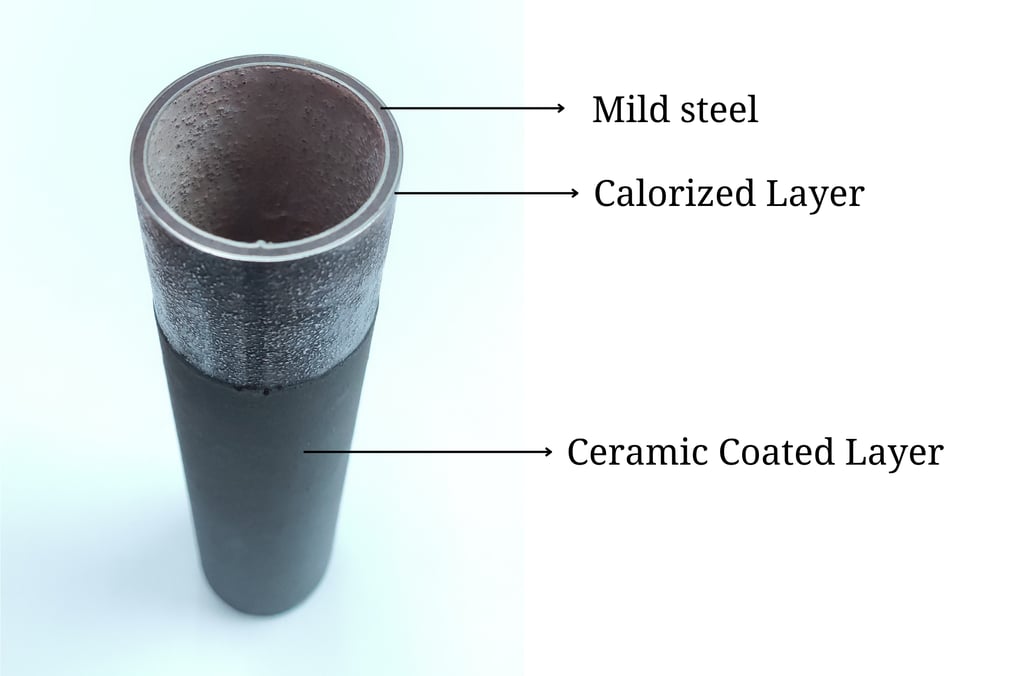

Daiwa Calorized Lance is the oxygen lance pipe, used for oxygen and carbon injection for steel making process mainly with electric arc furnace but also use at the blast furnace. Customers can use this oxygen lance pipe with various applications as below:

- Cutting steel scrap, melting, and refining steel at an electric arc furnace.

- Injection of carbon, lime powder, and/or other additives for adjusting grades of carbon steel or special steel.

- Removing slag inside the oxygen converter.

- Other uses of this oxygen lance pipe can provide strong resistance against heat, oxidation, sulfuration, vanadium attack, etc.

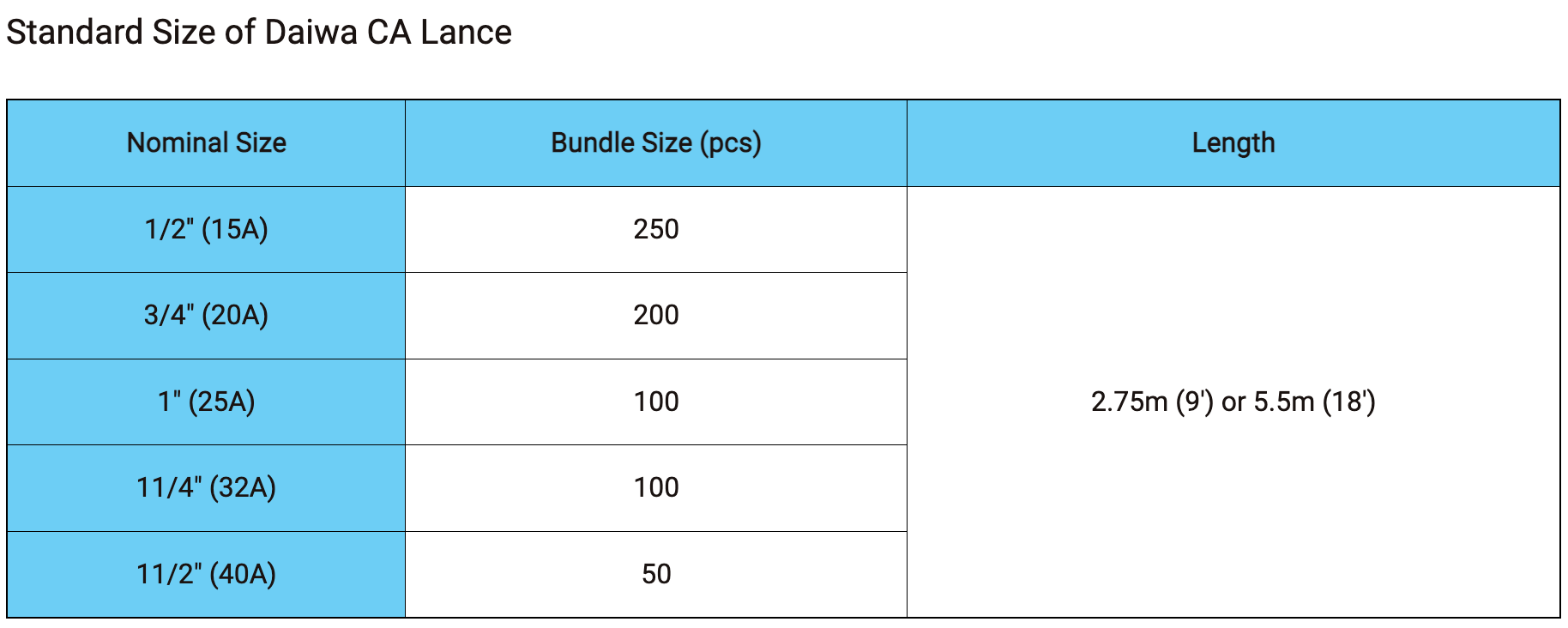

・Daiwa Lance can manufacture 2-1/2" O.D. lance pipes to supply the appropriate size lance pipe for a planned trash-burning furnace according to the design of the facility.

・Daiwa Lance has extensive experience in manufacturing oxygen lance pipes enables us to stably supply not only small lance pipes but also lance pipes up to 2-1/2" O.D. to meet customer requirements for blowing oxygen and other substances.

・Daiwa Lance can design 2-1/2" O.D. lance pipes based on the design specifications of trash-burning furnaces and electric arc furnaces to ensure fit and workability.

Conclusion

Larger diameter oxygen lance pipes are required as a result of the trend toward larger electric furnaces and incinerators so that more oxygen can be blown into the furnace during the shorter heating operation time.

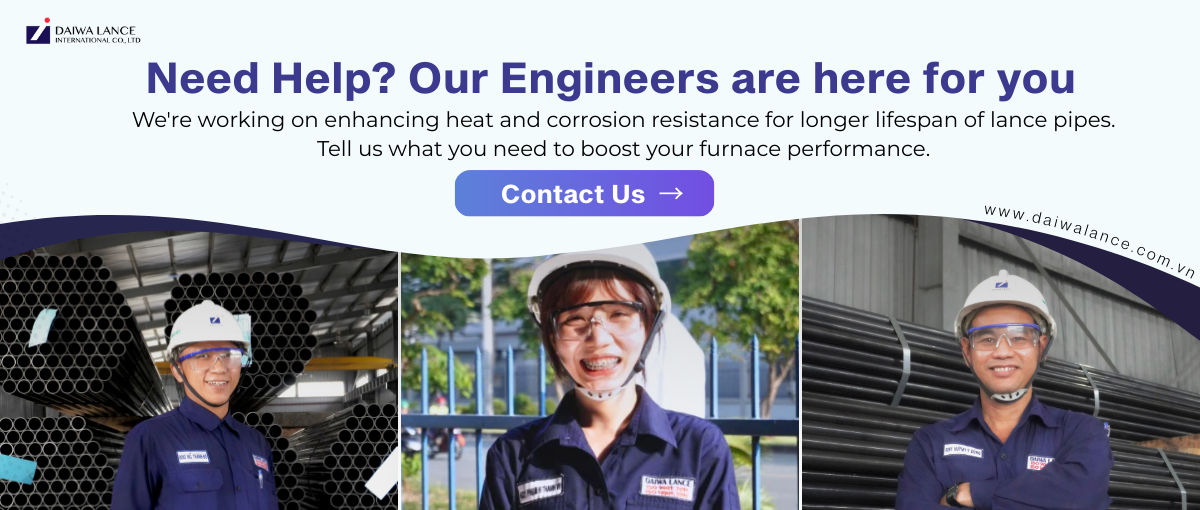

If you wish to know more about our solution for larger O.D of oxygen lance pipes used, please contact our dynamic team to support you during your journey.

- Category:

- Daiwa Lance Products

- Keyword:

- SDGs

- Oxygen Lance

- Thermic Lance