About Slag

To put it simply, slag is a byproduct of steel production coming from the process of separating or refining metal from its ore.

Because of its definition, many people may associate slag with waste or rubbish and basically unusable. However, indeed this so-called waste leftover is a surprisingly valuable material for construction, especially cement production.

In this regard, slag is quite awesome, right?

But imagine, if you’re a steel worker, a metal supervisor, or a production manager who is moving back and forth under a super hot heat blast furnace or electric arc furnace just struggling day and night to remove all the redundant slags from casting equipment or torpedo cars, and so on, I bet that you'll have no liking for slag anymore no matter how amazing the benefits that it brings.

So in this case, do you think that we can remove these stubborn slags with ease by grinding, chipping or burning it with flames?

Well, the answer can be Yes or No depending on the position where the slag locates.

Just jump to the next part and see how we can carry out slag removal to quench your thirst for curiosity.

RELATED POST

Slag Removal | Grinding Slags with Drilling Mill

No wonder that slag removal is hard and dangerous work.

Therefore, without a proper tool that fits your specific purposes, the harmful impact can be caused by unintended misuse as a consequence.

Here we suggest some of the most common tools to make your finished steel products smooth and clean by removing unnecessary slags efficiently.

A drilling mill is a type of specialized equipment used to grind industrial waste such as steel slag and water slag into powder.

The steel slag is processed by crushing, transporting, grinding, and drying.

A drilling mill is an ideal piece of equipment for grinding steel heavy slag.

But the demand of high cost, installation time, skilled labor as well as complex machine instructions can be a hindrance to those who choose this type of slag removal equipment.

Particularly, a drilling mill is only suitable to grind heavy slags.

Slag Removal | Chipping Slags with Hammer

Another way to make slags gradually start to peel off is by using a chipping hammer, especially for small slags.

And this is considered as one of the most conventional methods to think about due to its easy availability.

With a handheld chipping hammer, the worker can manually perform the action of shattering persistent slags piece by piece.

Even though the operation of a chipping hammer is not so difficult and dangerous, its productivity and effectiveness becomes a real question because using a chipping hammer requires a great deal of labor efforts and repetitive tasks which brings less value into the entire automation process of steelmaking.

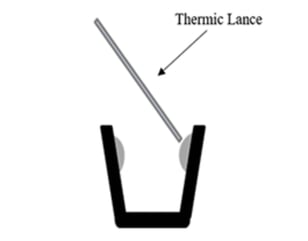

Slag Removal | Smelting Slags with Thermic Lance

So how about cleaning a pile of slags by burning them with high-temperature flames?

Is it possible to carry out the removal with not only heavy slags but also small slags?

Well, it can be one possible way for sure.

As you may be well aware of, slag has a melting point of around 1,780℃ and is difficult to remove from a metal system with a lower melting temperature.

For that reason, in order to use this kind of slag removal, we need a material that can generate a higher temperature than the melting point of slag to melt it down and remove it.

In this case, thermic lance can be a choice for your consideration.

Thermic Lance can produce a super high heat rate up to 4,000℃ with Fe + O2 → Fe2O3 + Heat reaction.

- Slags stuck in plant decks

- Slags stuck in working floors

- Slags stuck in ladle furnace

- Slags stuck in casting equipment

- Slags stuck in mixer cars

- And so on

Daiwa Thermic Lance Working Principle

To make it clearer, we will introduce Daiwa Lance Slag Removal Solution for your reference.

Daiwa Thermic Lance (TL) is a steel pipe filled with inner tube and wires and creates super high temperature and powerful flame.

Chemical reaction of Thermic Lance during the combustion process is as below:

Fe + O2 → Fe2O3 + Heat reaction (up to 4,000℃)

It burns itself by blowing oxygen and produces high heat.

The principle is to harness oxidation heat of high temperature by providing pressurized oxygen inside the ignited steel pipe.

Generally the inside of a metal tube contains steel wire that promotes combustion.

If you want to know more about the types of Thermic Lance and how to properly use it, please click below article for more information.

- Category:

- Daiwa Lance Products

- Keyword:

- introduction to thermic lance