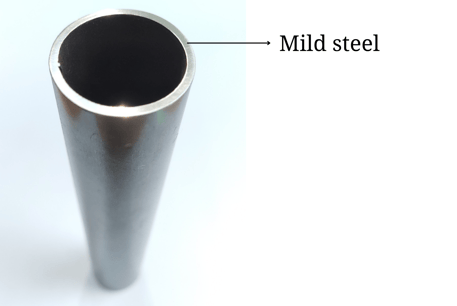

Mild Steel pipe is one of many pipes that are used for the steel production process. Understanding this global demand, Daiwa Lance has produced SC lance pipe with many characteristics that could be used for different purposes of the steel production process. In this blog, by showing the effective characteristics of SC Lance, displaying the appeal points of SC Lance it is possible to make you have enough information that is highly accurate so that you are able to approach us without hesitation afterward.

What is Daiwa SC Pipe?

Daiwa SC Lance pipe is a mild steel pipe made by HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, without oil and grease on the pipe. Daiwa SC Lance generates a high temperature of over 3,000℃ by blowing oxygen and melting solidified steel, and slag on equipment.

Application of Daiwa SC Lance Pipe

Applications of Daiwa SC Lance Pipe:

- Opening Tap Hole

During the steel production by Blast Furnace steel mills, the initial application is to use lance pipes to open the tap hole so that the production process will get enough flow of the melted iron. Taphole is situated at the bottom of the furnace and needs to open the hole periodically to take out the molten iron and slag.

- Removing Slag:

The accumulation of solidified slag trapped in mechanical equipment in continuous casting equipment after the ironmaking process comes to an end can deteriorate operating performance over time. After pouring out liquid steel, the workers will use SC Lance pipe to clean stuck metal inside various areas inside Steel Mill Plant after processing time.

Removing Slag Sticking on the Floor inside Steel Mill

- Cleaning Purpose:

The accumulation of solidified slag trapped in mechanical equipment such as ladle cars or tundish nozzles in continuous casting equipment after the ironmaking process comes to an end can deteriorate operating performance over time. The SC Lance pipe is called to be used over here once again for the cleaning furnace, removing slag on the wall of the ingot case, and pig iron at the iron notch of the blast furnace.

Cleaning Ladle Furnace after Long Time Using

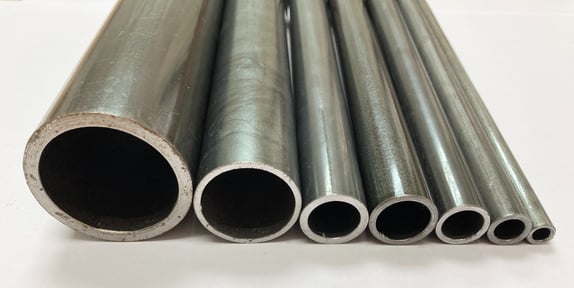

Connection Types of Daiwa SC Lance Pipe

- Plain ends -- Some customers prefer to use plain ends of SC lance pipe without any connection when one piece is enough to complete the job.

- Thread & socket: it is easy to connect 2 pipes no need to waste half-used pipe. For this type, we use a wrench for tightening while connecting the pipe.

- Press Coupling: it's an easy connection type, by just hitting pipes and coupling them together to the wall or floor a coup of times then connecting.

* Special Chamfering: Besides the normal Plain End type, we also can prepare this special Chamfering due to customers' requirements and it is easy to insert a holder in this case.

Conclusion

Daiwa Lance has created an SC lance pipe with a variety of properties that may be utilized for a variety of purposes in the steel production process. In this blog, we want to provide you with enough correct information to allow you to approach us without hesitation after seeing the effective qualities of SC Lance and showcasing the attraction points of SC Lance.

Please let us support you with additional questions you are having and feel free to contact us through the inquiry page below.

- Category:

- Daiwa Lance Products

- Keyword:

- SDGs

- Oxygen Lance

- Thermic Lance