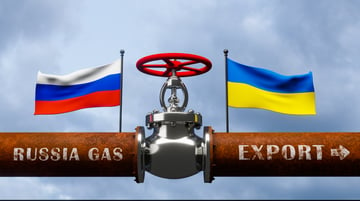

The impact of the conflict between Russia and Ukraine causes fluctuation in prices in global energy markets. With steel prices and supplies fluctuating due to the Russian and Ukraine situation continuing, it would be ideal to be able to use steel materials that support cost savings, energy savings, and natural resource savings over previous years.

Steel producers are somehow aware of the high consumption of mild steel pipes used in blast furnaces/electric arc furnaces, but are unaware of better alternative products. They want to know how to minimize the use of raw materials and natural resources in the steel manufacturing process during inflation.

In this blog, we would like to introduce you to how to save energy costs by using more effective oxygen pipes, and in the meantime also can support the environment and protect the labor.

Impact of Material Cost due to Reduction of Number of Pipes

Daiwa CA Lance lasts 3 to 10 times longer than mild steel. The pipe has Calorized layer and Ceramic coating both for the outside and inside of the pipe and can stand for a much longer time than normal carbon steel pipe, and used for oxygen/carbon injection for steel making, mainly with an electric arc furnace. When blowing oxygen and carbon, the lance pipe is inserted into the melted iron. If a normal carbon steel pipe is used, the pipe consumes immediately when inserted in melted iron compared to CA Lance pipe.

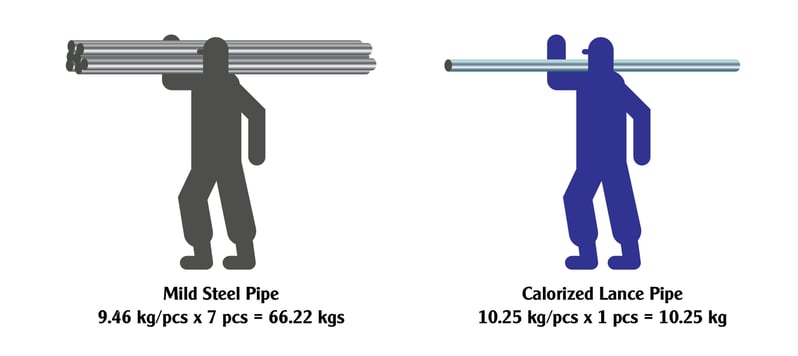

For steel manufacturers, using oxygen bellows to support and accelerate the steel production process is an important part. The cost of even using Calorized steel pipe is also reduced through the high quality of the steel pipe and the efficiency in use.

The low number of pipes used compared to Mild Steel also helps to reduce the use of inventory space. Less unloading of goods, indirectly, helps workers reduce the time to move steel pipes before they are used. At the same time, the time used for labor will be less, and be used to focus on other jobs.

For the environment, the use of steel pipes of better quality and longer use time helps to reduce the exploitation of the earth's resources. The problems of water and gas pollution of the earth for the accompanying pig iron ore mining are also minimized.

Impact of Energy Cost due to Shorter Heating Time

-

Consumption reduced

The time it takes to smelt steel is reduced, which helps to reduce fuel, oil, and gas, which are the main fuels used in steel production. Currently, due to the conflict between Ukraine and Russia, fuel prices tend to be unstable and fluctuate. Therefore, the use of steel production materials with high efficiency can help to reduce energy, that's what manufacturers are looking for.

Operating and manipulating right in front of the furnace is very dangerous. This requires a high degree of concentration of the oxygen bellows operator in front of the furnace. Using oxygen bellows for a longer time will help workers reduce the number of times to change tubes during operation. Also, the changing time of pipe would be reduced, this would protect the operator standing before the Furnace. Besides saving time in the steel production process, reducing the number of pipe changes helps to reduce the risk of occupational accidents for the company. This is what steel manufacturing companies focus on in minimizing to protect their employees.

Pipe Dimension: 33.3 x 2.3 x 5,500 (mm)

- Heating time reduced

The heating time of the Electric furnace count as tap to tap time, measure the minutes take our produced pig iron from the tap hole of the furnace to the next take out.

We have the specific experimental test in one Electric Arc Furnace steel mill Viet Nam to see how effectively Calorized Lance can perform to shorten the heating time of steel production. During the process, a Mild Steel pipe blows oxygen to the furnace, and the full heating time to finish the melting process is 65 minutes. Then the steel mill uses Calorized Lance pipe to see the performance, and it takes only 60 minutes to finish the full melting process. Generally, 5 minutes saving for each heating time is counted, and for steel manufacturing, this is a huge saving as cost savings (working times and energy costs)

Conclusion

Prices in global energy markets fluctuate as a result of the war between Russia and Ukraine. With steel costs rising as the situation in Russia and Ukraine worsens, it would be wonderful to be able to employ steel products that save money, energy, and natural resources compared to prior years.

Daiwa Lance, a leading steel pipe manufacturer, is one alternative place that supports keeping the steel production Viet Nam and many countries stable during this unpredictable period.

Please let us support you during your journey to make your production and operation as easy as they can be.

- Category:

- General Topics

- Keyword:

- oxygen lance pipe