Daiwa Calorized Lance Pipe has gained a reputation for its exceptional ability to withstand high heat and resist oxidation, making it a popular choice in steelmaking furnaces around the world. However, the market has seen an influx of Calorized products that lack proven effectiveness. In this article, we aim to shed light on the 3 key characteristics that define a high-quality Daiwa Calorized Lance Pipe.

Mininum Consumption

A significant issue in the lancing industry revolves around the rapid consumption and oxidation of oxygen lance pipes caused by extreme heat. These factors significantly reduce the lifespan of the pipes. The main reason for this rapid consumption is the lack of optimized coatings on the inner and outer surfaces of the pipes, making them vulnerable to environmental factors.

To overcome these challenges, Daiwa Calorized Lance Pipe has been meticulously designed with advanced technology to extend its lifespan by 3 to 10 times compared to regular mild steel pipes. For instance, while a mild steel pipe may require 3 to 7 replacements per heat, Daiwa Calorized Lance Pipe only needs 1 replacement.

Here's how it accomplishes this feat:

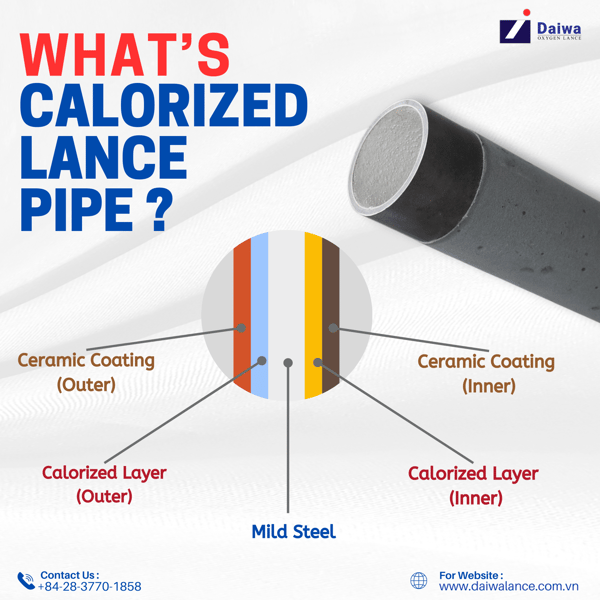

- Calorizing Process: The calorizing process, involving the diffusion of aluminum into the steel pipe, is at the heart of this feature. By doing so, it creates a highly durable aluminum-iron alloy, known as the calorized layer, on both the inner and outer surfaces of the mild steel core. This layer drastically improves heat and oxidation resistance, allowing the pipe to endure high-temperature environments. As a result, the need for frequent replacements is significantly reduced, cutting down on material consumption.

- Ceramic Coating: To withstand the extreme temperatures within steel melting furnaces, Daiwa Calorized Lance Pipe is equipped with layers of refractory ceramic coating. This layer reinforces the pipe's heat and wear resistance, ensuring that it can function optimally for longer periods. This durability, even in harsh conditions, minimizes the need for additional material consumption in the form of replacement pipes.

RELATED POST

Superior Quality

Daiwa Calorized Lance Pipe is synonymous with top-notch quality. Our layered structure and advanced technology make our product a standout choice in the lancing industry. Here's how we guarantee our superior quality:

- Premium Material Selection: The foundation of quality starts with the careful selection of premium raw materials. Daiwa Lance ensures that only the finest materials are used in the manufacturing of our Calorized Lance Pipes, resulting in enhanced durability and heat resistance.

- Meticulous Manufacture Processing: Every step of the manufacturing process, from the precise diffusion of aluminum to meticulous production, reflects the commitment to quality. What further solidifies this commitment to quality is that each stage of the manufacturing process undergoes rigorous inspection in accordance with ISO 9001 and 14001 standards, ensuring the highest quality at every level.

Click here to see our certifications on ISO 9001 and ISO 14001.

Cost-Effectiveness

Investing in Daiwa Calorized Lance Pipe ultimately translates to cost savings in the long run. The main reason for this boils down to the mass production at our advanced manufacturing facilities. Here's how Daiwa Calorized Lance Pipe delivers on cost-effectiveness:

- Extended Lifespan: Thanks to the calorized layer and ceramic coating, Daiwa Calorized Lance Pipe boasts an extended lifespan. The 3 to 10 time reduction in the frequency of replacements not only saves money on buying new pipes but also minimizes the downtime associated with maintenance.

- Efficient Resource Use: The minimal consumption of materials, as a result of the pipe's durability and customization options, leads to resource efficiency. You won't waste money on unnecessary pipe replacements, and you'll have the right-sized tools for the job, reducing material wastage.

- Size Optimization: The availability of various sizes ranging from 1/2” to 1-1/2”, including the custom size 3/4" x 1.3m and 1-1/2" x 9.0m, means that you can select the ideal pipe size that matches your production needs. This reduces the chances of purchasing oversized pipes that might result in material waste.

We have just highlighted the 3 essential features of Daiwa Calorized Lance Pipe. If you are curious to experience the exceptional quality of this product firsthand, we invite you to request a sample. This will allow you to witness for yourself the excellence that has been described. Click the link below to contact our customer support team who is always ready and available to respond to your inquiries within 24 hours, excluding holidays and weekends.

- Category:

- Daiwa Lance Products