When it comes to technical products, the buyers are not only captivated by the unique features but are equally concerned with the product's structure and sizes. For example, with a diameter of approximately 3/4" and a length of 2.75 meters, Daiwa Calorized Lance Pipe is ideal for medium to small foundries facing space limitations. Whereas, in case of a larger foundry with more room to spare, an option with the same outer diameter but a length of 5.5 meters can be chosen, resulting in valuable time savings during pipe replacement. At Daiwa Lance, we understand the importance of making well-informed decisions. That's why we are dedicated to providing you with all the information you need about the structure and size options of our Calorized Lance Pipe. This way, you can confidently choose the perfect fit for your specific production needs.

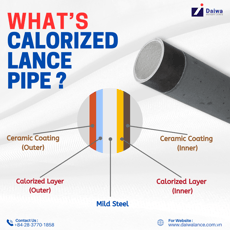

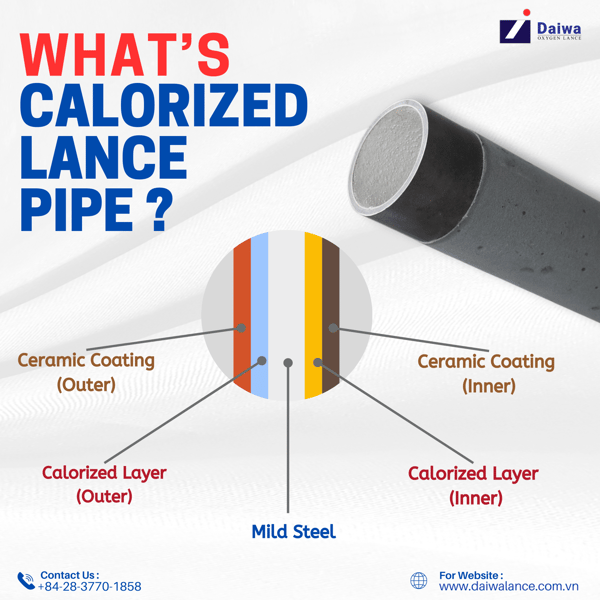

Structure of Daiwa Calorized Lance Pipe

As mentioned in our previous article discussing the applications of Daiwa Calorized Lance Pipe, one of its most remarkable features is its ability to inject and blow various gases, including oxygen and carbon, into furnaces such as EAF and incinerators. Additionally, it serves as a protective tube for thermocouples, ensuring accurate temperature measurements in molten metal environments with extremely high temperatures. As a result, the structure of Daiwa Calorized Lance Pipe has been specifically designed to meet the unique demands and requirements of these working environments.

The structure of Daiwa Calorized Lance Pipe is carefully crafted with a layered design, following a specific order from the inside out:

- Ceramic Coating (Inner Surface)

- Calorized Layer (Inner Surface)

- Mild Steel Core

- Calorized Layer (Outer Surface)

- Ceramic Coating (Outer Surface)

Now, let's delve into the distinct qualities and attributes of each layer within Daiwa Calorized Lance Pipe, uncovering the secrets that make it a truly exceptional product.

- Mild Steel: Mild steel, known for its low carbon content (ranging from 0.05% to 0.25%), offers a multitude of benefits. Its lightweight nature makes it ideal for mold-making, as it ensures ease of processing and good load-bearing capabilities. Additionally, it exhibits resistance to wear and tear, making it a reliable choice for standard oxygen lance pipes. However, it is important to note that mild steel has lower heat resistance.

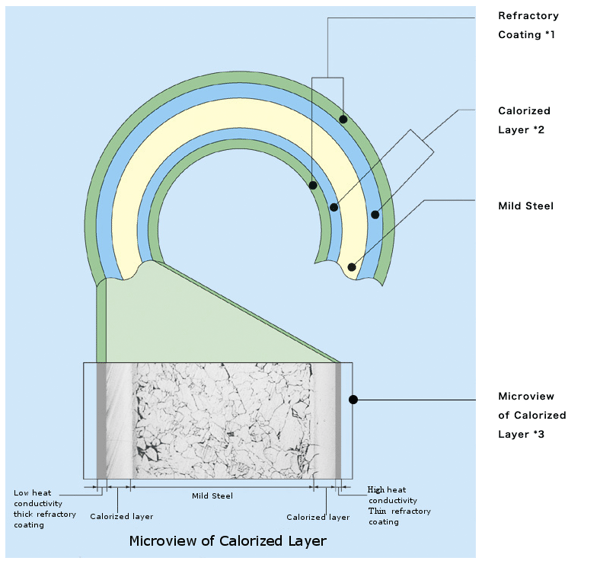

- Calorized Layer: For this reason, calorized layer is cleverly diffused into the inner layer of mild steel when the heating temperature reaches up to 1,000°C, creating a durable aluminum-iron alloy. This alloy enhances the heat resistance of the pipes by 3 to 7 times compared to a regular mild steel pipe while exhibiting excellent oxidation resistance. This significantly extends the lifespan of the steel pipe, despite the external conditions within the steel melting furnace.

- Ceramic Coating: The temperature inside a steel melting furnace is typically very high, sometimes reaching up to 1,600°C. Therefore, simply penetrating aluminum-iron (calorized layer) into mild steel is insufficient. Moreover, if the calorized layer is too thick, the pipe becomes overly brittle and prone to breakage. At this point, the ceramic coating layer plays the role of an effective refractory material, reinforcing the pipe's heat and wear resistance, without compromising its effectiveness and longevity.

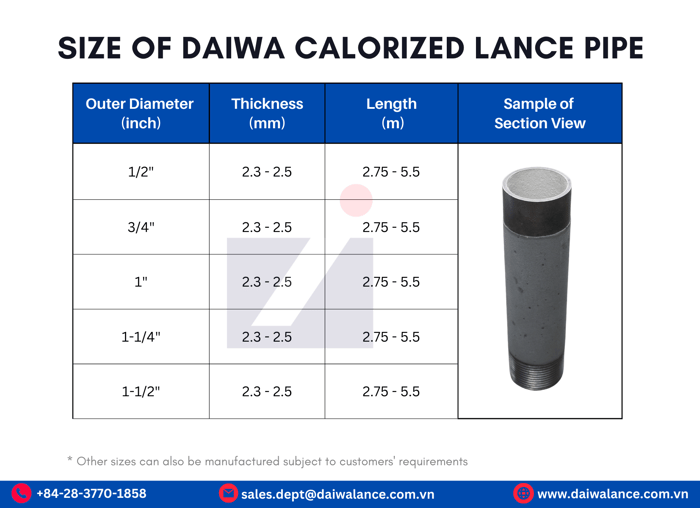

Common Sizes of Daiwa Calorized Lance Pipe

In addition to the structure, size is another important parameter that needs to be taken into consideration. Below is a summary table of the most common sizes of Daiwa Calorized Lance Pipe for your convenience.

Outer Diameter

Daiwa Calorized Lance Pipe comes in various sizes, with an outer diameter ranging from 1/2" to 1-1/2". Among these options, the 3/4" pipe stands out as the most popular choice. This is because it offers convenience when injecting oxygen into steel melting furnaces and is compatible with the machinery and equipment inside the furnace.

Thickness

There are two basic thicknesses to ensure optimal use of the Daiwa Calorized Lance Pipe, which are 2.3 mm and 2.5 mm. By simpifying the options and only offering the most appropriate thicknesses for Daiwa Calorized Lance Pipe, the buyers can avoid unnecessary confusion and lengthy decision-making when it comes to using the steel pipe.

Length

The length of Daiwa Calorized Lance Pipe is a critical factor in optimizing its performance. If the buyers have ample space and an automatic manipulator to support it, opting for a 5.5-meter pipe can greatly reduce the time spent connecting new pipes when the old one is consumed. This smart decision can save valuable time and improve efficiency. However, if the buyers have limited space and are concerned about handling long and heavy pipes, a 2.75-meter pipe may be a more practical solution. It allows for easier maneuverability and ensures smooth operation in compact areas.

These are just a few examples of the common and typical sizes of Daiwa Calorized Lance Pipe. If you are a first-time buyer of Daiwa Calorized Lance Pipe or would like more information on selecting the right pipe size, please do not hesitate to contact Daiwa Lance's customer support team for detailed information by clicking the link below.

Practical Applications of Other Different Sizes (Custom Sizes)

Custom Large Diameter (2 1/2" OD)

The demand for Daiwa Calorized Lance Pipes with a 2 1/2" OD is on the rise, despite being a size rarely used. This is driven by the increasing needs of incinerators and large EAF furnaces. However, there are only a few suppliers that can offer Calorized Lance Pipes in this size.

Take a look at the actual image below to see the significantly larger size of Daiwa Calorized Lance Pipe with a 2 1/2" OD compared to the commonly used pipes at Daiwa Lance.

This larger size is specifically designed to meet the unique requirements of incinerators and large EAF furnaces, which is blowing a larger amount of oxygen into the large-scale furnaces.

- For incinerators: Incinerators are often used to generate heat and electricity, so more oxygen needs to be blown into incinerators. Inadequate oxygen can result in incomplete combustion, leading to the release of harmful pollutants, such as carbon monoxide (CO) and unburned hydrocarbons. Therefore, an oxygen-rich environment can help achieve more complete combustion, leaving behind less waste materials.

- For large EAF: Large EAF contain a substantial amount of scrap steel and require a significant amount of heat to melt it. With a greater volume, more oxygen is needed to maintain a high-temperature environment and ensure efficient refining.

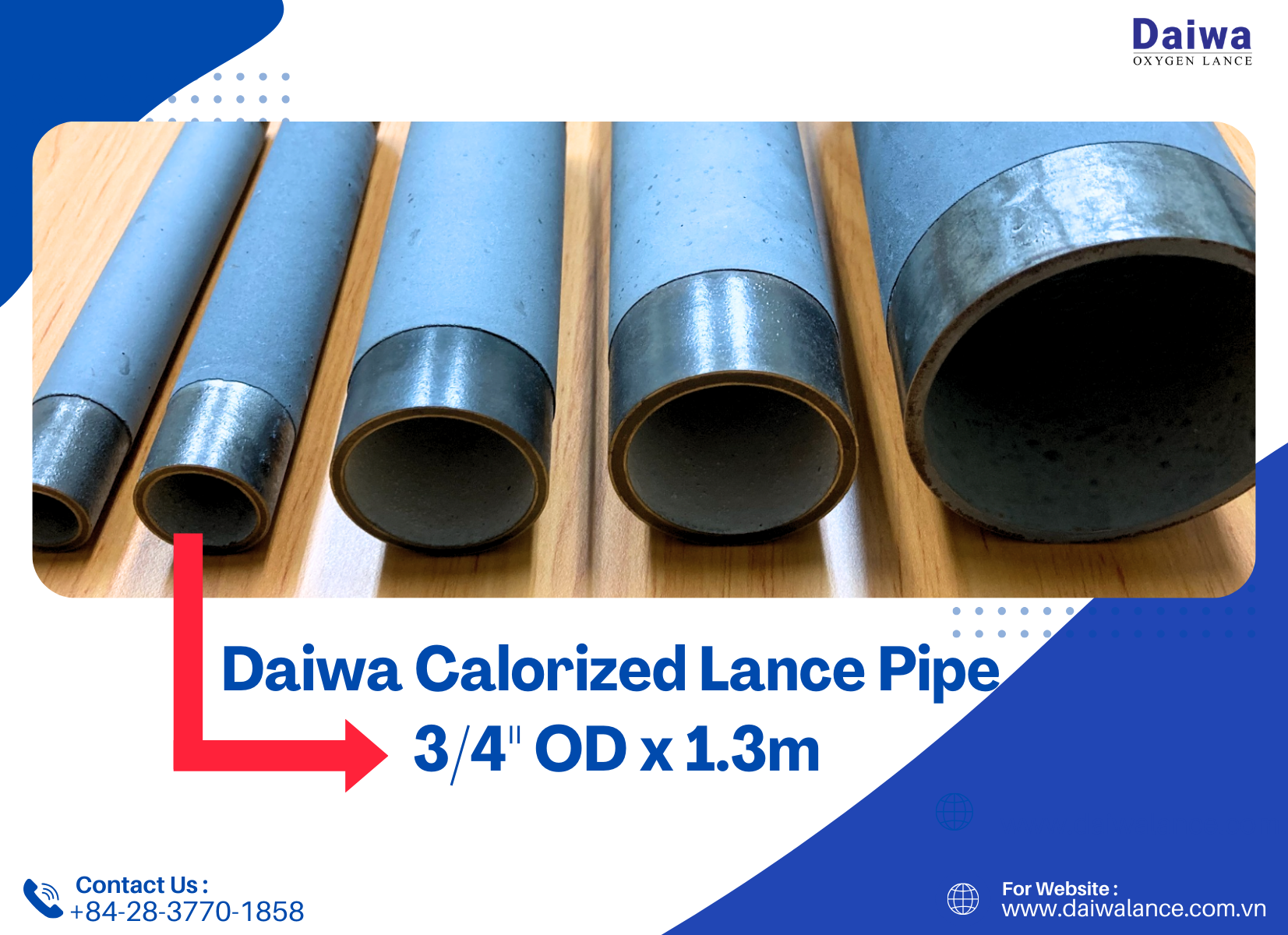

Custom Short Length (3/4" x 1.3m)

Conversely, compared to the demand for larger-sized pipes mentioned above, Daiwa Lance can fully produce and meet the need for smaller-sized Daiwa Calorized Lance Pipes, such as 3/4" x 1.3m. In this case, the pipe can be used effectively for the purpose of removing slags and cleaning scrap to prepare for a new steel smelting process. Below, you'll find an image showcasing the smaller-sized Daiwa Calorized Lance Pipes with a diameter of 3/4" and a length of 1.3m.

Conclusion

The size and structure of Daiwa Calorized Lance Pipe are crucial in selecting the right product for steel and metallurgical manufacturing applications. Making the correct choice in size and structure can improve product performance and longevity, as well as optimize the steel smelting and refining process.

As a company with years of experience in the production of Daiwa Calorized Lance Pipes, Daiwa Lance takes pride in offering flexibility in customizing the size and structure of the Calorized Lance Pipe to meet the specific needs of customers in the steel and metallurgical production process. If you have any related requirements for customizing the size of Daiwa Calorized Lance Pipe products, please do not hesitate to contact us by emailing sales.dept@daiwalance.com.vn and subscribe to our weekly blog to receive the most valuable information.

- Category:

- Daiwa Lance Products