Are you struggling to find reliable information about Daiwa Calorized Lance Pipe? Look no further! In this blog post, we have gathered all the essential details about Daiwa Calorized Lance Pipe, including its definition, manufacturing technology, structure, applications, types, sizes, and pipe joining methods. We understand that finding all this information can be challenging, so we have made it easy for you. By reading this blog post, you will gain a comprehensive understanding of this special product in just 5 minutes. So, sit back, relax, and let us guide you through the world of Daiwa Calorized Lance Pipe.

What is Daiwa Calorized Lance Pipe?

Daiwa Calorized Lance Pipe (also known as oxygen blowing lance, oxygen blower, oxygen blowing lance, oxygen lance pipe, high temperature resistant lance pipe, or ceramic coated aluminum pipe) is a type of lance pipe mostly used to inject oxygen and carbon or other additives in the steelmaking process. In order to reach a high level of heat and oxidation resistance, Daiwa Calorized Lance Pipe will need to undergo a calorizing process.

What's the Technology for Making Daiwa Calorized Lance Pipes?

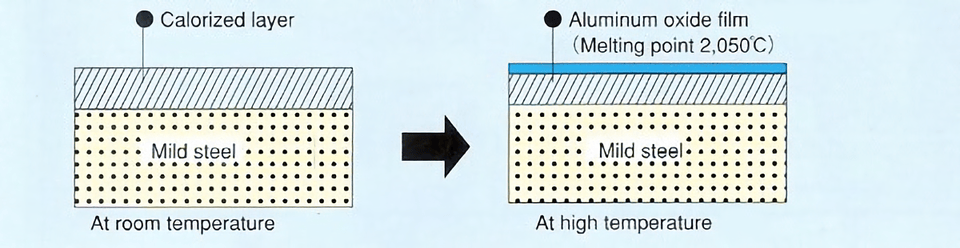

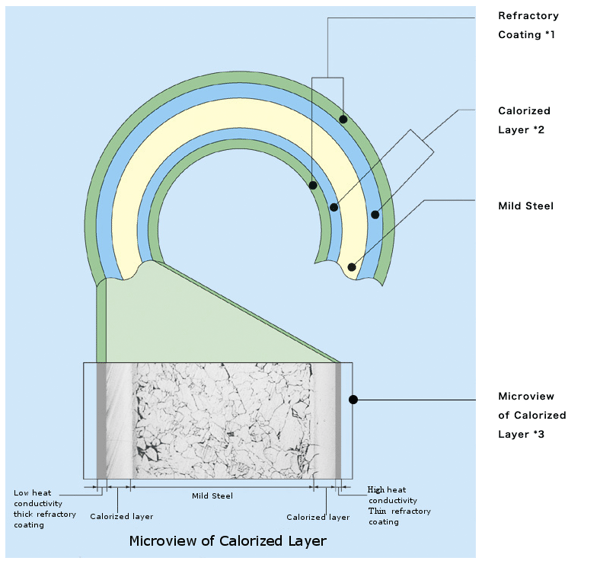

The technology used to produce Calorized Lance Pipe is called "Calorizing," or in other words, "aluminum diffusion." Calorizing is a surface modification process that diffuses aluminum into steel pipes both internally and externally. The purpose of the calorizing process is to protect the base metal from severe oxidation and corrosion caused by the high temperatures in the furnace or harsh environments.

RELATED POST

How is Daiwa Calorized Lance Pipe Manufactured?

To produce Daiwa Calorized Lance Pipes, a diffusion technology will be used. Mild steels will be heated to temperatures reaching 1,000°C, then aluminum penetrates the material, creating a durable aluminum-iron alloy (known as the calorized layer) that coats both the inner and outer surfaces of the mild steel.

Next, the product undergoes a ceramic coating process to enhance its heat and oxidation resistance when exposed to high-temperature environments.

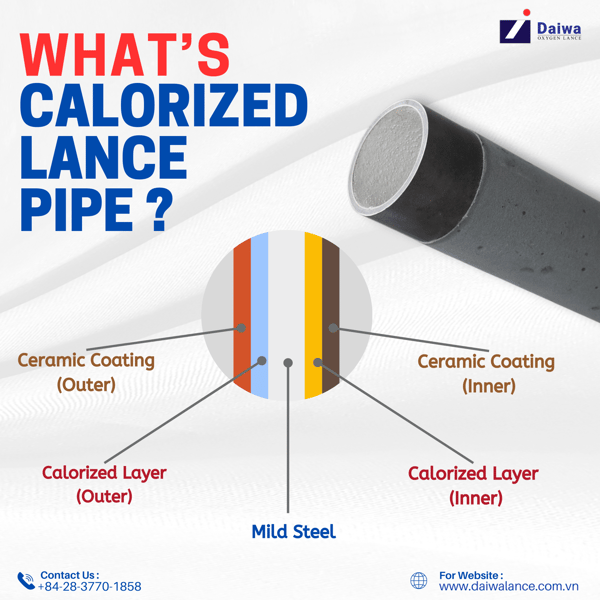

What is Structure of Daiwa Calorized Lance Pipes?

Daiwa Calorized Lance Pipes typically consist of the following components:

- Ceramic Coating (Inner Surface)

- Calorized Layer (Inner Surface)

- Mild Steel Core

- Calorized Layer (Outer Surface)

- Ceramic Coating (Outer Surface)

What are Applications of Daiwa Calorized Lance Pipes?

Daiwa Calorized Lance Pipe finds extensive usage in the steel industry, offering many beneficial applications. Let's explore its primary uses in this sector below.- Inject/blow oxygen, carbon or other gases in Electric Arc Furnaces (EAFs).

- Increase the oxygen supply source in the incinerators (trash-burning furnaces).

- Remove/clean slags inside oxygen converters molten irons on the floor.

- Open tapholes.

- Reduce carbon contents in the induction furnace.

- Serve as a protection tube for thermocouples when measuring temperatures in molten metal.

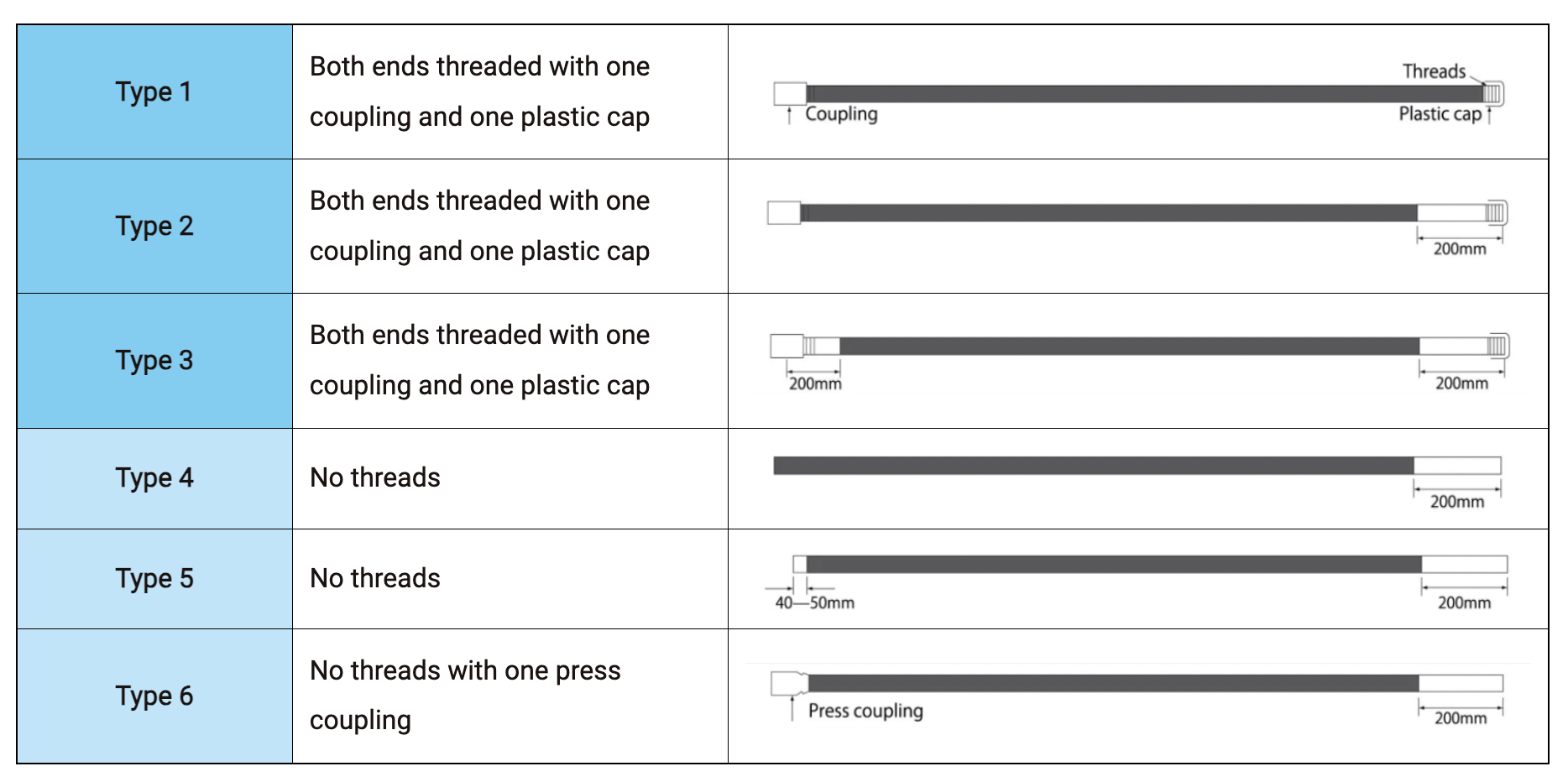

How Many Types of Daiwa Calorized Lance Pipes are there?

There are 6 types of Daiwa Calorized Lance Pipes as shown in the picture below.

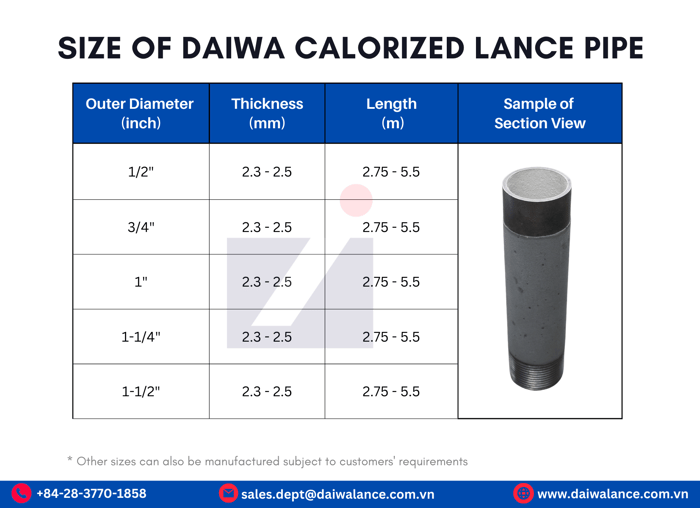

What are Sizes of Daiwa Calorized Lance Pipes?

There are many options available for the size of Daiwa Calorized Lance Pipe, and the most common sizes are summarized in the table below.

Apart from the standard sizes mentioned above, we can also provide other custom lengths such as 3/4" x 1.3M or 1-1/2" x 9.0M, and custom OD ranging from 1/2" to 1-1/2" based on specific requirements of customers.

(If you want to check other sizes of Daiwa Calorized Lance Pipe, click the link below to contact our customer support team who is always ready and available to respond to your inquiries within 24 hours, excluding holidays and weekends).

What are Connection Methods for Daiwa Calorized Lance Pipes?

To save costs and materials when using Daiwa Calorized Lance Pipe, we can utilize unused pieces by connecting two pipes together. Currently, there are 3 methods to connect Daiwa Calorized Lance Pipes, including:

- Thread & Socket

- Welding

- Threadless - use Daiwa Press Machine

To learn more about Daiwa Press Machine, please click to download the materials below.

Download Catalogue: Step-by-Step Guide to Connect Calorized Lance Pipes with Daiwa Press Machine

How to Buy Daiwa Calorized Lance Pipes?

Now that you have all the information you need about Daiwa Calorized Lance Pipe, you may be wondering how to purchase this product. Don't worry, it's a simple process. To place an order or get further support, simply click the link provided below or send an email directly to sales.dept@daiwalance.com.vn. Our team is ready to assist you with any inquiries you may have.

- Category:

- Daiwa Lance Products