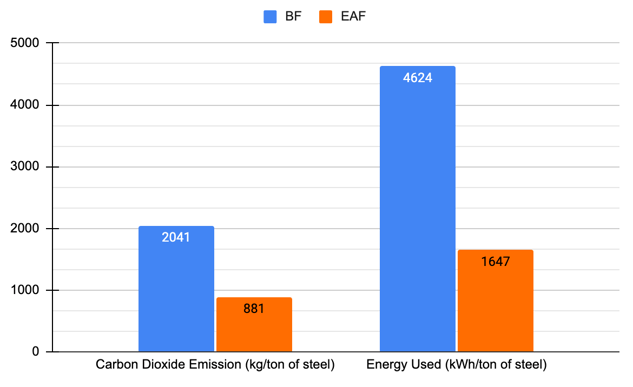

Steel production involves two types of furnaces: blast furnaces and electric furnaces. While blast furnaces are notorious for their staggering carbon emissions, electric furnaces offer a much more eco-friendly alternative, aligning with the Sustainable Development Goals (SDGs). However, new furnace companies may not be familiar with the credibility of Daiwa Lance Lance products, hindering their contribution towards achieving SDG goals. To build client confidence in Daiwa Lance, we provide timely professional and basic knowledge information on the steel market and our contribution to SDGs.

Steel production involves two types of furnaces: blast furnaces and electric furnaces. While blast furnaces are notorious for their staggering carbon emissions, electric furnaces offer a much more eco-friendly alternative, aligning with the Sustainable Development Goals (SDGs). However, new furnace companies may not be familiar with the credibility of Daiwa Lance Lance products, hindering their contribution towards achieving SDG goals. To build client confidence in Daiwa Lance, we provide timely professional and basic knowledge information on the steel market and our contribution to SDGs.

Carbon Emission of Blast Furnace vs Electric Furnace

Daiwa Lance's Contribution to SDGs

At Daiwa Lance, we strive to create a stable and balanced world by reducing our environmental impact during production and work. To achieve this, we make every effort to align with the SDGs, including creating a safe and healthy working environment (SDG 11) and controlling air and gas emissions to contribute to decarbonization efforts (SDG 13).

- Great and Safe Working Environment:

As part of our commitment to creating a safe and healthy working environment, we conduct regular examinations to monitor the air quality and oxygen levels within our plant. We adhere to the guidelines set out in SDG 11 and prioritize the safety and well-being of our workers, in line with SDG 14.

- Air and Gas Emission Control for both Internal Protection and Contribution to Decarbonization:

During the manufacturing process, certain air and gas emissions are released, making it necessary to control and monitor gas emissions to comply with government regulations. We manage our heating system to minimize air waste and protect our workers' working environment while contributing to a cleaner atmosphere on Earth. - Water Treatment to Protect the Environment:

After the Mother coils are slit, the edges are transformed into Steel Scrap and utilized as steel production materials for the Electric Furnace. The effluent from the Tubing Mill machine, which contains some oil for manufacturing, is recycled within the facility after undergoing chemical treatment and is never discharged into the environment. To maintain a clean and safe working environment, we have installed dust collection devices within our plants to efficiently absorb any dust produced during the manufacturing process.

Water Treatment Area at Daiwa Lance

- Following ISO and JIS Standards:

At Daiwa Lance, we follow ISO and JIS standards to ensure that our products are of high quality and safety standards, without causing any harm to the environment.

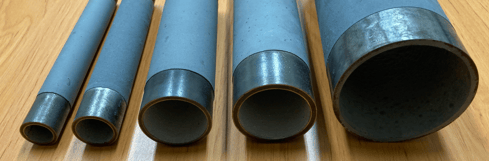

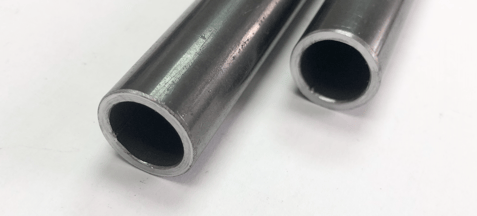

Daiwa Lance pipes for the Developing Technology from BF to EF

Daiwa Calorized Lance is the oxygen lance pipe, used for oxygen and carbon injection for steel-making processes mainly with electric arc furnaces but also use at the blast furnace. Customers can use this oxygen lance pipe with various applications as below:

- Cutting steel scrap, melting, and refining steel at an electric arc furnace.

- Injection of carbon, lime powder, and/or other additives for adjusting grades of carbon steel or special steel.

- Removing slag inside the oxygen converter.

- Other uses of this oxygen lance pipe can provide strong resistance against heat, oxidation, sulfuration, vanadium attack, etc.

- Opening iron notch and tap hole Blast furnace and Electric Furnace.

- Removing of metal and slag stuck to mixer car, converter, and Electric Furnace.

- Cleaning ladle nozzle and tundish nozzle in continuous casting equipment.

- Fusing and cutting steel piles and large scrap objects.

Daiwa SC Lance is an oxygen lance pipe that can generate a high temperature of over 3,000°C by burning itself and melting solidified steel and slag on equipment. This oxygen lance pipe can use to remove the following things

- Slag on the wall of the ingot case.

- Pig iron at the iron notch of a blast furnace.

- Slag in the ladle.

- Steel-slag mixture at the slag notch and iron notch of the blast furnace

Conclusion

If you have any questions or concerns regarding the handling of Daiwa Lance pipes, our sales department and agents are always available to assist you. We are committed to providing our customers with the best service possible and ensuring that they can transport our oxygen-lance pipes safely and confidently.

- Category:

- General Topics

- Keyword:

- oxygen lance pipe

- Calorized Lance Pipe