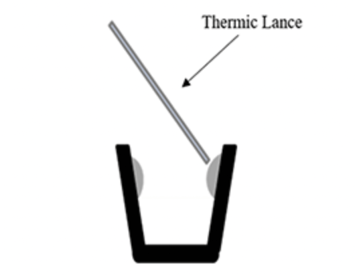

The Thermic Lance Pipe, generally called thermal lance burning bar, is a remarkable steel pipe that contains an inner tube and wires, resulting in a powerful flame and incredibly high temperatures. Through the Fe + O2 → Fe2O3 + Heat reaction, the Thermic Lance can generate a heat rate of up to 4,000℃. By supplying pressurized oxygen to the ignited steel pipe, it harnesses the oxidation heat of high temperatures. Typically, the inside of the metal tube contains steel wire, which aids in the combustion process. Daiwa Lance takes pride in manufacturing the Thermic Lance (TL) as one of their high-performance products. Given the diverse uses of the Thermic Lance, it is crucial to understand the specific type that should be employed for optimal efficiency at the manufacturing site.

In this blog post, we are excited to present our latest innovation, the Daiwa Thermic Lance. Our goal is to provide you with comprehensive information about this remarkable tool, enabling you to fully grasp its capabilities and ensure optimal performance.

Introducing Daiwa Thermic Lance Pipe:

Daiwa Thermic Lance (TL) is a steel pipe burning bar with a hollow core packed with steel wires and is mostly used for heating, melting, and cutting large or heavy metal materials. The Thermic Lance is a remarkable steel pipe burning bar that serves multiple purposes, including fusing metals, cutting scraps, and cleaning furnaces. Its ingenious design allows for the utilization of high-temperature oxidation heat by introducing pressurized oxygen into an ignited steel tube. In simpler terms of Thermic Lance, this burning bar employs the thermal cutting method to disperse heat and burn materials effectively.

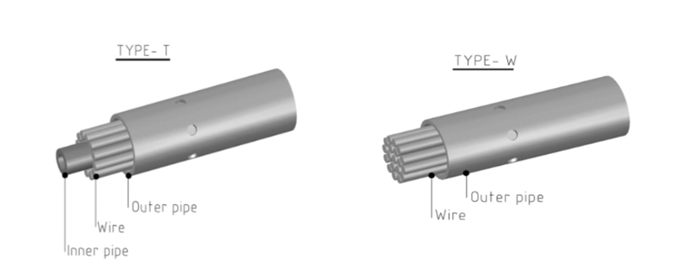

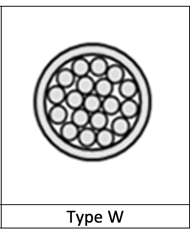

Typically, this thermal lance contains steel wire inside, which aids in combustion. To cater to the diverse requirements of end-users, Daiwa Lance offers two types of Thermic Lance, which are Type T and Type W.

Types of Daiwa Thermic Lance

・Thermic Lance is used as a burning bar for cleaning stuck metal, drilling material, and scrap cutting.

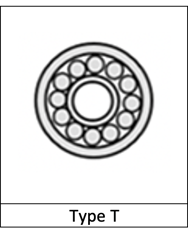

Type T, featuring a blend of wires and an inner pipe, unleashes a fierce and rapid straight flame capable of effortlessly splashing out, creating holes, or disintegrating materials with astonishing speed. This remarkable burning bar variant is well-suited for a wide range of materials including carbon steel, iron, slag, copper, aluminum, and brass, among others.

Type W with a full pack of wires produces a wider flame at a higher temperature than Type T. This thermal lance's type distinct feature is to dissolve solid materials that have high melting points such as stainless steel, nickel, concrete, refractory materials, natural stone, etc.

Applications of Thermic Lance:

-

Applications of Daiwa Thermic Lance Pipe:

Slag, with this thermal lance's high melting point of approximately 1,780℃, poses a challenge when the burning bar comes to removing it from a metal system with a lower melting temperature. To effectively eliminate slag, we require a material that can generate a temperature higher than the melting point of the slag, allowing the thermal lance to melt away. In this scenario, Daiwa Thermic Lance (TL) emerges as an ideal choice for consideration. With the burning bar's capability to produce an astonishingly high heat rate of up to 4,000℃ through the reaction of Fe + O2 → Fe2O3 + Heat, the thermal lance can effortlessly melt down and remove the stubborn slag.

Removing Slag Sticking on the Floor inside Steel Mill

When it comes to transforming scraps into usable materials for production, there are various techniques available. One effective method involves utilizing an Oxygen Lance, particularly for cutting scraps with high hardness or large sizes. Daiwa Thermic Lance, this burning bar with inserted wires or wires and an inner pipe, is specifically designed for tasks like fusing metals. This ingenious tool harnesses high-temperature oxidation heat by introducing pressurized oxygen into an ignited steel tube. The burning bar typically contains steel wire, which aids in the combustion process. With Daiwa Thermic Lance, cutting and shredding scraps becomes a breeze, making this thermal lance an ideal solution for recycling and repurposing materials.

Testing Experience in Daiwa Lance for Cutting Scraps

Conclusion

By introducing pressurized oxygen to the ignited steel pipe, the Thermic Lance harnesses the incredible heat generated through the oxidation process. The inner tube of the metal pipe contains steel wire, which plays a crucial role in aiding the combustion process. Daiwa Lance takes immense pride in manufacturing the Thermic Lance (TL) as one of their exceptional high-performance products. Understanding the specific type of Thermic Lance to employ for optimal efficiency at the manufacturing site is of utmost importance, considering its diverse range of applications.

If you wish to know more about the suitable oxygen lance pipe as a competitive burning bar for melting down the trash, feel free to contact our dynamic team to support you during your journey.