Daiwa Lance Products

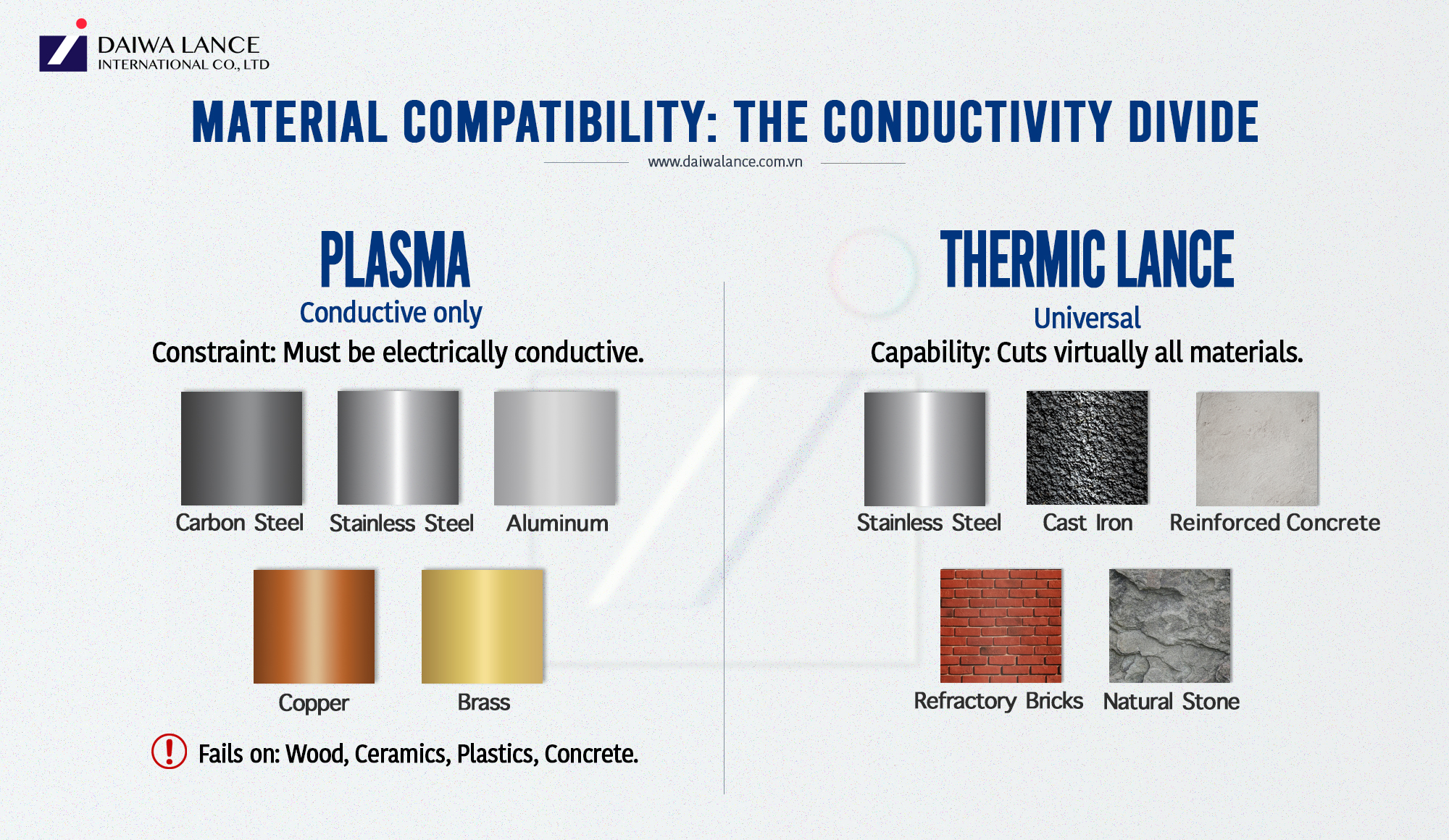

Plasma Cutting vs. Thermic Lance: Key Differences

Continue Reading

Daiwa Thermic Lance (also known as thermal lance or burning bar) is a consumable steel pipe packed with inner steel wires that creates an intense iron oxidation reaction (4Fe + 3O₂ → 2Fe₂O₃ + heat), generating a powerful flame up to 3,600°C without noise or vibration, allowing materials to be cut quickly through this exothermic chemical process.

Daiwa Thermic Lance is widely used in steel mills, foundries, shipyards, construction sites, and mining operations for cutting, demolition, and melting works on high hardness materials such as stainless steels, heavy steel scraps, reinforced concrete structures, offshore oil rig legs, refractory concretes, fire bricks, natural stones, and steel pipes in embankment construction.

* Note : The consumption rate of Daiwa Thermic Lance varies widely depending on the conditions in which the lance is used.

Based on industrial cutting requirements, Daiwa Thermic Lance is available in multiple structures:

Based on your specific cutting requirements and target material dimensions, we recommend optimal Daiwa Thermic Lance dimensions with appropriate oxygen gas flow rates and oxygen pressure specifications to generate the necessary heat output and flame intensity for sustained combustion when cutting various target materials as follows.

Custom sizing available for specialized projects - contact our engineering team for technical consultation.

When Thermic Lance rod burns through during cutting operations, we offer 4 professional connection methods that easily attach to standard lance holders, allowing you to extend cutting time without interruption.

Key Industrial Applications of Daiwa Thermic Lance:

Steel Mills & Foundries:

Heavy-Duty Cutting & Demolition:

Marine & Offshore Industries:

Mining & Construction:

Pressurized oxygen running through iron wires can generate a high temperature up to 4,000°C.

The fast ignition of Daiwa Thermic Lance can significantly help to reduce the time required for cutting works.

Surface treatment with layers of insulation ensure paramount safety for operators against direct contact with flame sparks in the furnace.

Q.

A.

A Thermic Lance (also known as thermal lance or burning bar) or is a cutting tool that uses oxygen and iron/steel pipes to create temperatures up to 3,600°C, capable of cutting through concrete, steel, and other hard materials by oxidation and melting.

Q.

A.

Thermic Lances can cut high hardness materials such as stainless steels, heavy steel scraps, reinforced concrete structures, offshore oil rig legs, refractory concretes, fire bricks, natural stones, and steel pipes in embankment construction. They're ideal for demolition, rescue operations, and industrial cutting applications.

Q.

A.

To prevent Thermic Lance burnout, maintain oxygen pressure at 8-11 bar, use an oxy-acetylene torch at 120-degree angle for ignition, and keep the lance dry and clean. Additionally, work in low-wind areas, gradually reduce oxygen flow when finishing cuts rather than shutting off abruptly, and ensure proper inner wire structure—wires shouldn't be too tight (blocking airflow) or too loose (causing wire fallout).

Q.

A.

To ensure safe operation, operators must wear complete personal protective equipment (PPE) including heat-resistant clothing, face shields, protective gloves, and ensure adequate ventilation in the work area. At Daiwa Lance, we provide comprehensive safety guidelines and training materials with each product to help operators follow proper safety protocols.

Q.

A.

Yes, we can provide comprehensive cutting guidance and professional training support for Thermic Lance operations. Our expert technical assistance covers thermal cutting techniques, step-by-step operational procedures, safety protocols, and cutting performance optimization.

For more tips on improving your furnaces with effective use and cost-saving benefits, click here to subscribe to our blog!

Learn more about our product materials here!