Ship breaking—also known as ship dismantling or ship recycling—is a billion global industry that handles the end-of-life disposal of ocean-going vessels to recover valuable materials—primarily steel, but also copper, brass, bronze, and resalable equipment.

Despite its profitability, the industry faces several operational difficulties: remote beach locations without infrastructure, harsh offshore weather, thick structural steel (50-100mm+), and the need for specialized cutting equipment that works without electricity in high-humidity environments. This is where cutting tool selection becomes critical.

In fact, not all ship parts need Thermic Lance. But some do—absolutely. These are the 5 hardest, thickest structural components where Thermic Lance isn't optional, it's essential. Let's break them down in the blog below.

What's the Purpose of Ship Breaking?

First, ship breaking isn't just about demolition—it's about precisely dismantling the rotten and out-of-date vessels after 30 to 40 years travelling to recover valuable materials like steel, copper, and bronze, which are worth millions.

So when we're dismantling ships, tool selection matters a lot. We need equipment that cuts precisely, not destroys. There are different options—cutting torches, thermic lances, hydraulic shears, or hand saws. But here's the key: every cut must be controlled and deliberate to preserve material value. When you choose the wrong tool, it means you're literally burning money.

RELATED POST

Understanding the Challenges in Ship Breaking

Ship breaking concentrates in coastal regions across South Asia (Bangladesh, India, Pakistan), Southeast Asia (Indonesia, Philippines, Malaysia), the Middle East (UAE), and Latin America (Brazil, Chile, Peru). These remote beach locations share 3 critical operational challenges.

- High humidity (70-90%) and salt spray rapidly corrode equipment, degrading oxygen regulators and electrical components.

- Tidal schedules restrict cutting to 6-8 hour work windows between tides.

- Remote locations lack electrical infrastructure—no power grids mean plasma cutters become unusable and generators cost hundreds of dollars daily in fuel.

These challenging ship breaking conditions require portable, oxygen-powered cutting tools that cut thick steel structures efficiently without electrical power.

Understanding Ship Structure for Cutting Operations

Before we talk about cutting, let's quickly understand what you're working with.

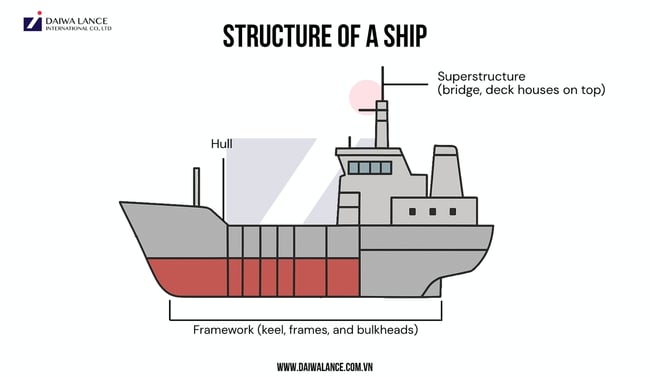

A ship's structure has 3 main layers: the hull (outer shell that keeps water out), the framework (keel, frames, and bulkheads—basically the skeleton), and the superstructure (bridge, deck houses on top).

Think of it like a building: the keel is the foundation, frames are the support beams, bulkheads are the walls, and decks are the floors. When you're ship breaking, you're cutting through these structural members—and some are way thicker than others. That thickness difference determines your cutting tool choice. Standard torches can handle thin plates fine. But for specific structural components are so thick, they'll eat your time and budget without proper equipment.

Now, let's dive into the specifics. In the next section, we'll show you 3 critical thick and heavy ship components where Thermic Lance isn't just helpful - it's absolutely necessary for efficient cutting.

3 Critical Ship Parts That Need Thermic Lance Cutting

#1: Keel (The Ship's Backbone)

The keel is the main longitudinal beam running along the bottom centerline of the ship—literally the spine of the entire vessel. Everything else connects to it.

|

Why It's Challenging |

How Thermic Lance Excels |

|

Because of the extreme thickness and high-strength steel composition over such long lengths, oxy-acetylene torches consume enormous time and labor - with flames that become unstable in offshore winds. Meanwhile, Thermic Lance cuts the same keel section in just less than 30 minutes. At 3,600°C, it burns straight through the thick steel regardless of rust, paint, or surface condition. |

#2: Hull Frames & Bulkheads

Frames (ribs) are the curved structural supports running perpendicular to the keel, giving the hull its shape. Bulkheads are vertical steel walls dividing the ship into watertight compartments. Together, they form the ship's internal skeleton.

|

Why It's Challenging |

How Thermic Lance Excels |

|

Standard cutting methods struggle with frames and bulkheads because you're not just cutting one plate—you're cutting through multiple welded layers simultaneously. Oxy-acetylene requires grinding welds first, then cutting each layer separately. Thermic Lance burns straight through the entire assembly—all layers, all welds—in shorter time. It reaches into tight corners thanks to the portable design, works at any angle (no need for flat contact surface), and doesn't care about rust or paint buildup. |

#3: Engine Bed & Mounting Structures

The engine bed is a massive steel foundation (often cast steel or thick welded construction) securing the main engine to the ship's keel and frames. Think of it as a 20-100 ton steel table bolted and welded throughout the engine room.

|

Why It's Challenging |

How Thermic Lance Excels |

|

Engine beds present a unique problem: they're made of cast steel, which is denser and harder to cut than regular plate steel. Oxy-acetylene torches take longer hours per section and often struggle to penetrate fully. Thermic Lance at 3,600°C doesn't care about material density—it burns through cast steel, welded layers, and mounting bolts per section versus conventional tools. In the cramped engine room where you can't fit large plasma rigs, Thermic Lance's simple rod-and-oxygen setup lets operators position in tight spaces easily. |

Key Takeaways: Beyond these 3 critical parts, you can use Thermic Lance on any ship structure that shares these characteristics: thickness over 50mm, multiple welded layers, difficult access locations, corroded or painted surfaces, or situations where you need cutting speed to meet tight schedules. Basically, if standard torches are struggling or taking too long, switch to Thermic Lance.

Safety Guidelines for Ship Breaking with Thermic Lance

Despite being a billion-dollar industry, ship breaking remains one of the most hazardous work environments globally. Workers face toxic exposure, structural collapse risks, fire hazards, and severe injury potential daily—safety concerns that persist across operations worldwide.

Beyond essential PPE (fire-resistant clothing, welding helmets, heat-proof gloves, and steel-toed boots), Thermic Lance operations require specific safety protocols:

- Maintain a Safe Distance: Always keep a safe distance (at least 1 meter) from the material being cut to avoid flying sparks and molten metal. Move Thermic Lance towards the cutting direction, keeping it in close contact with the base material.

- Control oxygen pressure: Set regulators to 8-11 bar. Too high causes dangerous splatter; too low prevents proper ignition.

- Ensure gas-free certification: Never cut near fuel tanks or enclosed spaces without certified gas-free status. Explosion risk is fatal.

- Secure fire watch: Keep CO2 or dry powder extinguishers within 5 meters. Assign someone to monitor for fires during and 30 minutes after cutting.

- Support structures first: Never cut load-bearing members without proper support. Sudden collapse kills.

Conclusion

Throughout this guide, we've covered ship breaking fundamentals—why precision matters when recovering millions of dollars in materials, the harsh realities of coastal operations (humidity, tides, no electricity), and basic ship structure knowledge you need.

Most importantly, you properly now understand the 3 critical components where Thermic Lance becomes essential: the keel (50-100mm backbone), hull frames & bulkheads (multi-layered skeleton), and engine beds (80-150mm cast steel foundations).

With this information, we assume that you now have a clearer understanding of the ship breaking challenges you're facing and the critical safety protocols for using Thermic Lance. Are you ready to see it in action?

We offer two ways to experience Thermic Lance firsthand:

- On-Site Demo – Our technical team visits your facility to demonstrate cutting performance on your actual materials.

- Online Training – Live virtual sessions covering operation, safety procedures, and best practices.

Whether you want hands-on experience or prefer remote learning, we're here to support you. Please contact Daiwa Lance today to schedule your demo or training session.

Moreover, if you need any detailed technical specifications, please click the link below to explore our complete product documentation.

- Category:

- Daiwa Lance Products

- Keyword:

- introduction to thermic lance