Speed and convenience are among the primary requirements when operators want to use quick release couplers to replace new pipes for Thermic Lances. With the pressed quick coupling, these requirements are fully met. In this article, we will guide you on how to use this type of quick connector, including specific requirements such as how to attach new Thermic Lance quickly and easily to achieve rapid changes of couplings.

What is Pressed Quick Coupling?

A pressed quick coupling for Thermic Lance is a rapid connection tool that allows operators to quickly attach new lance pipes during operations.

When to Use Quick Connection Coupling for Thermic Lance?

Pressed quick couplings are essential in several operational scenarios:

- Time-Saving Operations: Save valuable time switching between lance pipes in steel mills, blast furnaces (BF), electric arc furnaces (EAF), or scrap yards where every second of downtime impacts productivity.

- Eliminating Threading Work: No more wasting time screwing pipes with sockets and threaded connections. Traditional methods require tools and careful alignment that consume valuable minutes.

- Fast, Tool-Free Connection: High-speed environments demand immediate response. Pressed quick couplings eliminate the need for wrenches or threading tools, allowing efficient operation even with protective gear.

- Immediate Safety Response: Enable immediate oxygen supply shutoff and lance removal to ensure steelmaking time isn't interrupted during emergencies or task switching.

How Pressed Quick Coupling Works?

Understanding the mechanism behind pressed quick couplings helps operators use them more effectively:

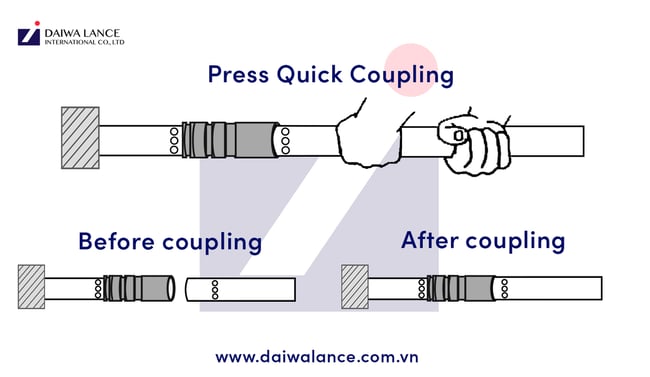

- Two-Part Design: The design consists of one pressed quick coupling end and one plain end of the new lance pipe.

- Connection Method: The operator simply hits the thermic lance with plain end and the pressed quick coupling together against a hard and flat surface such as a wall or floor a few times to help the two ends secure together. It's designed for speed and simplicity during high-temperature cutting operations.

- Sealing Mechanism: No separate sealing materials are needed because the pressed quick coupling features a special design with two ridges on its head. When the two pipes are struck together, these two ridges lock tightly together quickly without requiring any additional sealing process.

How to Attach New Thermic Lance Faster with Pressed Quick Coupling?

Below is how to attach a new Thermic Lance quickly using Pressed Quick Coupling.

- Step 1: Start with two same-diameter pipes: one fitted with pressed quick coupling and one plain end.

- Step 2: Use strong force to connect them together.

- Step 3: Strike the lance against a hard and flat surface such as a floor or wall 2-3 times until you hear a distinct clicking sound, indicating the plain end pipe is properly secured between the ridges.

Watch: Pressed Quick Coupling In Action - Video Tutorial

For a visual demonstration of how to connect Thermic Lance quickly and easily with pressed quick coupling, please refer to our instructional video guide that shows the complete process step-by-step.

Conclusion

Pressed quick coupling is a game-changer for Thermic Lance operations. They let you swap lance pipes in seconds, keeping your work flowing without frustrating delays. Less downtime, safer operations, and better productivity—that's what you get in tough industrial settings.

Not sure which pressed quick coupling size fits your Thermic Lance? Just reach out to us. Our engineers will help you pick the right one based on your pipe diameter, operating pressure, and what you're cutting. Click here to reach out to our technical team and learn more about implementing quick couplings in your operations.

- Category:

- Daiwa Lance Products

- Keyword:

- introduction to thermic lance