Daiwa Thermic Lance is a well-known and widely used variant of the oxygen lance pipe, which is primarily utilized for oxygen blowing systems in Electric Arc Furnace (EAF) operation across steel mills, foundries, and mining facilities worldwide. Despite its widespread adoption in the global steel manufacturing industry and metallurgical operations, many professionals remain unfamiliar with Thermic Lance technical specifications and cutting methods.

To save you significant time, we have compiled all the technical information, applications, and benefits of Daiwa Thermic Lance in the blog below.

What is Daiwa Thermic Lance?

Daiwa Thermic Lance, sometimes called a thermal lance or burning bar, is essentially a specialized steel pipe filled with steel wires that creates an incredibly hot cutting tool. Think of it as a consumable torch that burns itself up while doing the work.

RELATED POST

How does Daiwa Thermic Lance Work?

Getting Thermic Lance going is straightforward. You start by igniting it with a conventional acetylene torch – just like lighting a giant matchstick. Once it's lit, pure oxygen is fed through the pipe from an oxygen cylinder and regulator. This oxygen flow is what transforms the lance from a simple steel pipe into a powerhouse cutting tool.

The magic happens through a simple but powerful chemical reaction. When you feed pressurized oxygen into the ignited steel tube, it triggers an iron oxidation process (4Fe + 3O₂ → 2Fe₂O₃ + heat). This exothermic reaction generates an intense flame reaching temperatures up to 3,600°C – that's hot enough to cut through most metals quickly and efficiently.

What makes Thermic Lances special is their thermal cutting method. Unlike other cutting tools, they work completely silently without any vibration, making them perfect for situations where noise is a concern. The steel wires inside the pipe keep the combustion going strong, essentially turning the entire lance into a high-temperature cutting flame.

What is Thermic Lance Used For? Real-World Applications That Matter

Wondering where you'd actually use a Daiwa Thermic Lance in the real world? The applications are more diverse than you might think. From massive industrial operations to specialized cutting tasks, here's where this powerful tool really shines.

Steel Mills & Foundries:

- Opening iron notch and tap holes in blast furnaces, electric furnaces, and cupola furnaces

- Removing stubborn solidified metals and slag buildup from plant decks, working floors, and ladle furnaces

- Cleaning blocked ladle nozzles and tundish nozzles in continuous casting operations

- Drilling through tough refractory materials on furnace walls when maintenance calls

Heavy-Duty Cutting & Demolition:

- Slicing through heavy steel scraps, stainless steel waste, and ultra-hard materials that regular tools can't handle

- Reinforced concrete demolition and precision concrete cutting applications

- High-rise building teardowns and wind turbine tower decommissioning projects

- Steel pile cutting and sheet pile removal operations

Marine & Offshore Industries:

- Vessel demolition, shipbreaking, and efficient used ship scrapping operations

- Offshore oil rig leg cutting and platform decommissioning

- Processing large scrap objects in busy shipyard environments

Mining & Construction:

- Cutting through crusher jaws and drilling pins on heavy mining machinery

- Steel pipe cutting for embankment construction and infrastructure projects

- Mining facility shutdowns and ore bin dismantling operations

- Natural stone cutting and specialized fire brick processing tasks

The bottom line? If you need to cut through something thick, tough, or seemingly impossible to penetrate, chances are a Daiwa Thermic Lance can handle it.

What Types of Daiwa Thermic Lance are Available?

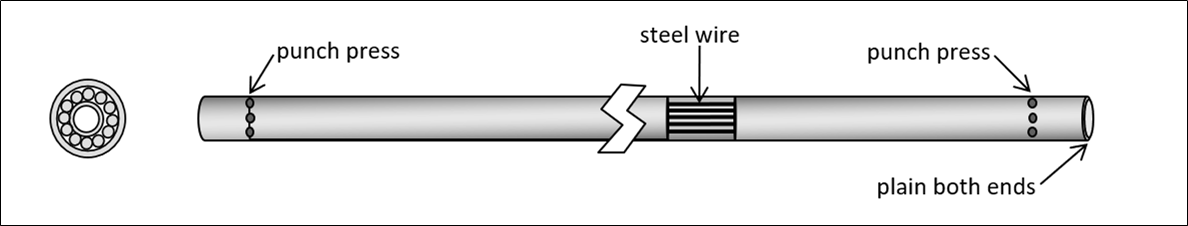

Daiwa Thermic Lance Type T - For Standard Industrial Materials

Daiwa Thermic Lance Type T features a mixture of wires and an inner pipe design that creates a straight flame at high speed. This concentrated heat can splash through materials, punch holes, or break up substances quickly and efficiently. Type T works particularly well on common industrial materials like carbon steel, iron, slag, copper, aluminum, and brass. It's your go-to choice for most standard metal cutting and scrap processing jobs.

Daiwa Thermic Lance Type W - For High-Temperature Applications

Type W comes with a full pack of wires that produces a wider flame at an even higher temperature than Type T. Its distinct feature is the ability to dissolve solid materials with high melting points that would challenge other cutting methods. This makes Type W ideal for tackling tough materials like stainless steel, nickel, concrete, refractory materials, and natural stone.

The beauty of the Daiwa Thermic Lance system lies in its simplicity – just acetylene ignition, oxygen flow, steel, and controlled combustion working together to create one of the most effective thermal cutting methods available, with options tailored to your specific material challenges.

What Sizes are Available for Daiwa Thermic Lance?

Here's the thing about Thermic Lances - size isn't just a number, it's everything. The diameter, thickness, and length you choose can make or break your cutting project success. Let's break down how to pick the perfect fit for your needs.

- Large Diameter, Long Lances: These are your heavy-duty workhorses. Perfect when you're tackling major industrial demolition or need to cut through massive steel structures. More power, deeper penetration.

- Smaller Diameter, Short Lances: Precision is the name of the game here. Skillful operators often love these for detailed work where control matters more than raw cutting power.

- Medium-sized Lances: The sweet spot for most applications. These versatile performers handle your everyday cutting tasks without breaking a sweat.

Below, you'll find the complete size specifications for both Daiwa Thermic Lance Type T and Type W. Each configuration is engineered for specific performance characteristics, so you can match your lance perfectly to your cutting requirements.

What Types of Connection for Daiwa Thermic Lance?

Method 1: Plain End Connections - Simple and Straightforward

What are plain end connections? Plain end Thermic L lance pipes come without any threading or coupling attachments. Think of them as the "standalone" option for your piping needs.

When should you use plain ends? This connection type works perfectly when you need just one piece to complete your job. Many customers love this option because it's cost-effective and eliminates unnecessary complexity. If your project doesn't require multiple pipe sections, plain ends are your best bet.

Key benefits:

- No additional fittings required

- Lower overall cost

- Quick installation for single-piece applications

- Minimal maintenance needs

Method 2: Thread & Socket Connections - Maximum Efficiency

How do thread & socket connections work? This popular connection method allows you to join multiple Thermic Lance together seamlessly. The threaded end of one pipe screws directly into the socket of another, creating a secure, leak-proof connection.

Why do customers prefer this method? Here's the game-changer: you won't waste half of your used Thermic Lance like you might with other connection methods. This means better material utilization and significant cost savings over time.

Perfect for:

- Multi-section installations

- Projects requiring pipe extensions

- Applications where you need to maximize pipe usage

- Situations where you want easy disassembly for maintenance

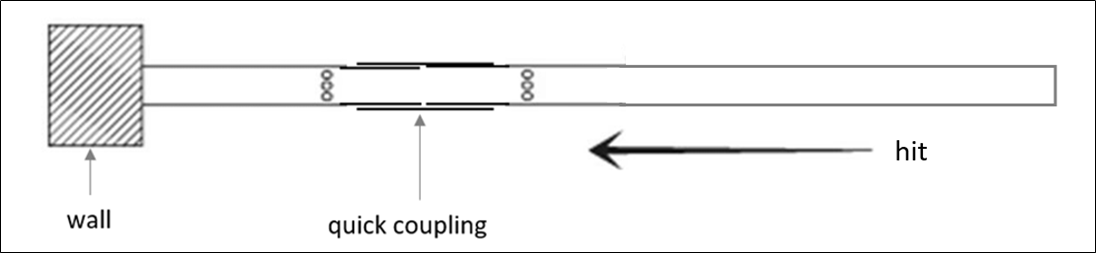

Method 3: Quick Coupling - Fast and Foolproof

What makes quick coupling so popular? Quick coupling is the speed demon of connection methods. Your operator simply needs to hit Thermic Lance and coupling together against the wall or floor a few times, and you're connected. It's that simple.

Why choose quick coupling?

- Lightning-fast installation

- Minimal training required for operators

- Reduced labor time and costs

- Virtually foolproof connection process

Most popular specification: The 1/4" (OD 13.8mm) x Length Type T is the go-to choice for most quick coupling applications. This size offers the perfect balance of strength and versatility for typical industrial applications.

Which Connection Method Should You Choose?

Your choice depends on your specific project requirements:

- Choose plain ends if you need a single pipe section and want the most economical option

- Go with thread & socket when you need to connect multiple pipes and want maximum material efficiency

- Pick quick coupling when speed of installation is your top priority

In addition, if you want to reduce the time spent connecting new lance tubes after finishing with the previous ones, you might want to consider rolled thermic lances as your go-to solution.

Here's why rolled format makes sense for your operations:

Extended Roll Format Available - Get custom lengths up to 30 meters or even longer, making them ideal for large-scale industrial projects and continuous cutting operations where efficiency matters most.

The key advantages:

- Less interruption during extended cutting tasks

- Faster workflow with fewer pipe connections needed

- Perfect for continuous operations where stopping to connect new tubes costs valuable time

- Customizable lengths to match your specific project requirements

This approach is particularly valuable for industrial cutting applications where minimizing connection time and maintaining cutting momentum can significantly impact your project timeline and overall productivity.

Still not sure which connection type works best for your application? Consider factors like installation time, material costs, maintenance requirements, and operator skill level. Each method has its sweet spot, and choosing the right one will save you time, money, and headaches down the road.

Conclusion

In conclusion, Daiwa Thermic Lance is a powerful and versatile tool that is widely used in various industries for heating, melting, and cutting large or heavy metal materials. With its extreme heat generation, user-friendly design, portability, safety features, and cost-effectiveness, Daiwa Thermic Lance proves to be an essential tool for a range of applications such as removing slag, cutting scrap, industrial demolition, and precision cutting. Whether you are in need of a large diameter lance for industrial purposes or a smaller diameter lance for artistic work, Daiwa Thermic Lance offers a range of sizes to suit your specific needs. To learn more about Daiwa Thermic Lance, be sure to explore our blog further and discover how this tool can enhance your work efficiency and productivity. To get in touch with our customer support team, simply click on the link below. Our dedicated team will provide you with a prompt response within 24 hours.

About Daiwa Lance

Established since 1997, Daiwa Lance has positioned ourselves as a pioneer in thermic cutting and oxygen lancing technology. Based in Ho Chi Minh City, Vietnam, we have been providing quality customer service and products with advanced Japanese technology.

We maintain the highest quality standards with ISO 9001:2015, ISO 14001:2015, and JIS G standards certifications. We have also expanded our reach globally, exporting to over 55 countries worldwide.

Visit us through our contact channels today: Email, WhatsApp, Contact Us form, or connect with us on Youtube, LinkedIn and Facebook.

- Category:

- Daiwa Lance Products

- Keyword:

- introduction to thermic lance

%20size%20CTA%20theo%20Nh%E1%BA%ADt%20%20(1)-2.png?width=1200&height=510&name=(400%20x%20170%20)%20size%20CTA%20theo%20Nh%E1%BA%ADt%20%20(1)-2.png)