Corrosion is a common problem that can weaken and deteriorate steel structures. In moisture conditions where oxidation occurs rapidly, corrosion is even more likely to happen. While we cannot completely eliminate corrosion, by taking proactive measures, we can reduce its impact and extend the lifespan of steel structures.

Steel Corrosion: Understanding the Process

Steel Corrosion Process

Steel corrosion is a chemical process that occurs when iron (the primary component of steel) comes into contact with oxygen and water (or moisture) in the environment. This process creates iron oxide compounds, commonly known as rust, which are typically reddish-brown in color.

Negative Impact of Steel Corrosion

- Reduced Strength: Steel corrosion (rust) reduces the cross-sectional area of steel, making the structure weaker and more prone to breakage.

- Loss of Aesthetics: The corroded surface of steel looks unattractive and diminishes its aesthetic value.

- Environmental Pollution: Some chemical compounds formed during the corrosion process can pollute the environment.

Factors Influencing the Rate of Steel Corrosion

- Humidity: High humidity accelerates the rate of corrosion.

- Temperature: High temperature increases the rate of chemical reactions, including corrosion.

- pH: Acidic or alkaline environments can accelerate corrosion rates.

- Presence of electrolytes: Electrolytes such as salts increase the conductivity of water, promoting corrosion.

- Stress: Internal stress in steel can create stress concentrations, increasing the susceptibility to corrosion.

RELATED POST

4 Ways to Enhance Corrosion-Resistance for Steels

Environmental Control

- Reduce humidity: Utilize methods such as ventilation and dehumidification to decrease the humidity level in the environment surrounding the steel.

- Control temperature: Maintain a stable temperature in the environment to reduce the corrosion rate.

- Eliminate corrosive substances: Remove corrosive substances like acids and salts to minimize their impact on steel.

Alloying

Alloying steel with specific elements is a crucial technique to significantly enhance steel corrosion resistance. Key elements like chrome and nickel form a protective oxide layer over the steel's surface, preventing corrosion.

Stainless steel is a typical example. The durability of stainless steels is largely due to the alloying process. Specifically, chromium, a primary alloying element in stainless steels, reacts with oxygen to create a passive film, shielding the steel from corrosion. This makes stainless steel highly resistant to rust and ideal for various applications. However ideal it is, the disadvantage of using stainless steels for better corrosion-resistance is that its price is quite high.

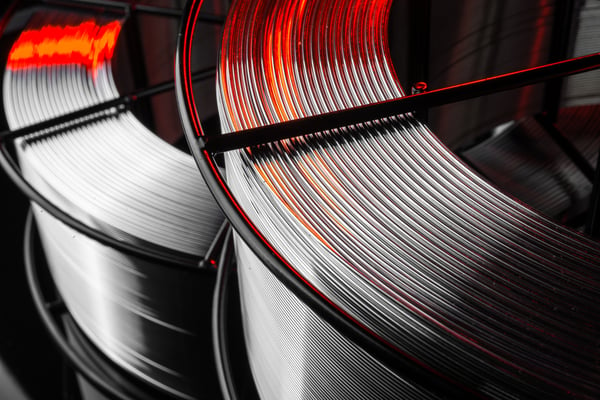

Metal Plating

Metal plating is a process where a thin layer of metal is applied to the surface of another metal. This layer acts as a barrier, protecting the underlying metal from corrosion and other forms of environmental damage.

Galvanization is a common method of metal plating where a layer of zinc is applied to the surface of iron or steel. Zinc is more reactive than iron, meaning it will corrode preferentially. This sacrificial protection prevents the underlying iron or steel from rusting.

Other examples of metal plating can include nickel plating, chrome plating, copper plating or gold plating.

Coating

Coating is a widely used technique to protect metals from corrosion. By applying a protective layer to the metal surface, it acts as a barrier between the metal and the corrosive environment, significantly reducing the rate of corrosion.

For example, polyester resin is one of the effective corrosion-resistant coatings. Polyester resin is a type of polymer that is widely used as a coating material due to its excellent corrosion resistance, durability, and versatility. The effectiveness of polyester resin lies in its ability to form an impermeable barrier that prevents corrosive substances such as acids, moistures, and extreme temperatures from reaching the underlying metal.

Conclusion

Above, we already introduced the process, negative impacts, influencing factors, and mitigation methods of steel corrosion to extend the lifespan of steel structures.

To meet the demands of our customers for good corrosion-resistant steel pipes, in Daiwa Lance, we have manufactured a type of corrosion-resistant steel pipes that combine both pre-galvanized steel pipes and polyester resin coatings in one product called Daiwa Color Pipe.

If you are interested in using this type of corrosion-resistant steel pipe for better performance in your factory, please do not hesitate to contact us by clicking on the link below.

- Category:

- Daiwa Lance Products