Daiwa CA Lance Pipe used in Eletric Arc Furnace

DAIWA CA LANCE is our main product, used for oxygen and carbon injection for steel making process mainly with electric arc furnace. When blowing oxygen and carbon into melted iron, the lance pipe is inserted in the melted iron. There are cases when customer use Daiwa CA Lance for Slags Removing, and Scaps Cutting.

Photo of Production Process inside Eletric Arc Steel Mill

RELATED POST

Why We should Choose Daiwa CA Lance Pipe instead of Thermic Lance for Slags Removing and Scraps Cutting in EAF?

During the process of melting steel inside Electric Arc Furnace Steel Mills, the process requires more oxygen, keeps cutting more slags directly to go down into melted iron. By then, many customers choose to combine by connecting Black Pipe and Calorzied Lance pipe, especially the size of 3/4"x1.3m just for this purpose. Daiwa CA Lance has Calorized layer and Ceramic coating both for the outside and inside of the pipe and can stand for a much longer time by this design.

Also, Daiwa CA Lance can be used for cleaning purposes, such as slags removed inside Electric Arc Furnace, or spilled metal, and removing slags on the floor. Besides the special size of 3/4" x 1.3m used for the Electric Arc Furnace Steel Mills, Daiwa Lance can produce different sizes for the same purpose depending on customers' requirements.

Daiwa CA Lance Pipes Connection Types

Daiwa CA Lance pipes can be connected in 3 different ways:

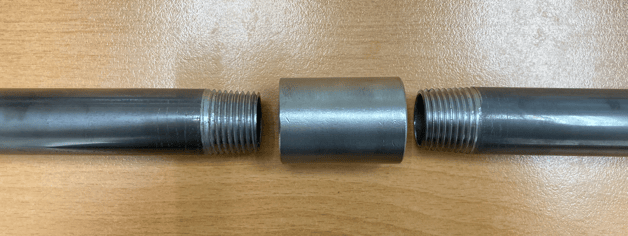

- Screw Socket: you can connect pipes together by hand with a socket and use a small tool like a wrench to tighten the connection. This way of doing can help you to connect pipes quickly and immediately while fully using the Calorized Lance Pipes without remaining anything.

Photo of Connecting 2 Pipes by Screw Socket

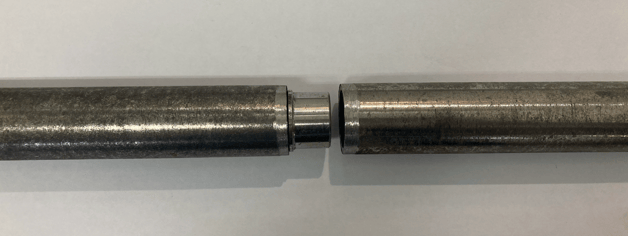

- Welding: You can use a single pipe or connect the pipes by welding them together to prevent air leakage. We recommend using an inner sleeve when welding the pipes to enhance strength and adhesion between the 2 pipes.

Photo of Welding to Connect 2 Pipes by Inner Sleeves

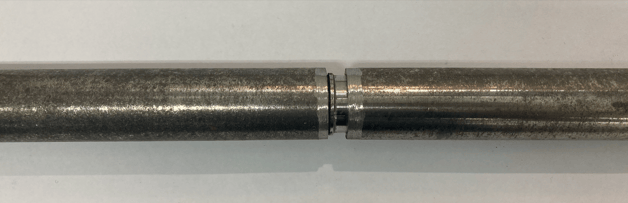

- Pressing Machine: With a higher volume for consumption, you can consider using this type thanks to the good air leakage resistance and easy operation.

Photo of Welding to Connect 2 Pipes by Pressing Machine

Conclusion

Many consumers buy a Calorized Lance pipe and then simply use it to blow oxygen or carbon into a massive electric furnace, not realizing it has additional uses and functions. Calorized Lance pipe, depending on its size, can also be used for slags removing from furnace walls or for scraps cutting into pieces for Eletric Arc Furnace in steel mills. For using an inside Electric Arc Furnace, the size of 3/4"x1.3m for a Electric Arc Furnace in Steel Mills is preferred by some customers.

If you wish to know more about our solutions for the suitable lance pipe for the Electric Arc Furnace, feel free to contact our dynamic team to support you during your journey.

- Category:

- Daiwa Lance Products