Steel manufacturing uses a significant amount of coke for production, which is particularly harmful to the environment. Coke ovens produce very harmful air pollution that can lead to cancer. Meanwhile, if waste water is not properly treated before being released into the environment, it is very dangerous to human health as well. Steel manufacturing emits an average of 1.83 tons of CO2 each ton of steel produced, making it a substantial contributor to global warming, accounting for roughly 3,3 million tons of CO2 yearly.

Besides producing long-lasting and good performance products to serve customers, we deeply understand building sustainable development through environmental protection, including human health.

Do you want to know more about our journey from the beginning building up ISO and keep doing it to follow the Global target by SDGs (Sustainable Development Goals)?

Daiwa Lance with ISO Certification

ISO standards are built on a cycle of continuous development, with benchmarks evolving to suit changing demands and objectives. ISO provides a wide range of standards, many of which are applicable to both small and big organizations.

We - Daiwa Lance International Co., Ltd - have always endeavored to preserve our steel pipe product by trying our best to meet ISO 9001 and 14001 standards for quality and environmental management for over twenty years, understanding the value of ISO certification to consumer confidence.

Daiwa CA Lance is our main product as a consumable product that supports the melting and refining in steel production. During the production process, wastes including air, chemicals, and dust are released into the environment. The whole process following ISO is controlled to treat wastes comprehensively before letting them out to the environment.

Let us show you how we treat waste to respect and protect both environment and human beings during our Production Process of Daiwa CA Lance as below:

Wastes treated during Production Process

1. Making Black PipeAfter slitting, the edge of the Mother coils will turn into Steel Scrap and will be reused as materials for steel production. In the meantime, waste water from the Tubing Mill machine, including some oil for production, is used inside the plant without letting it out into the environment and is reused after having chemical treatment. Mud's coming out from this process is waste that could affect the environment. So, we hire one specialized agent to take care of this to resolve the mud effectively.

2. Calorizing and Ceramic Coating

We have dust collecting systems that are set inside the plants to absorb the dust. Even this dust will not directly be harmful to the environment. However, good setting up machine and system will create a well working environment since we do care about our employees' health. On the flip side, this dust is collected and then treated as industrial waste following government regulation before letting it out to the environment. Our heating system is controlled precisely as air waste so that we can protect not only the working environment for our employees but also contribute fresh air on Earth.

We have monthly and quarterly checks by the government and one environmental quality company so that not only follow the regulation but also with the mindset of building a sustainable environment.

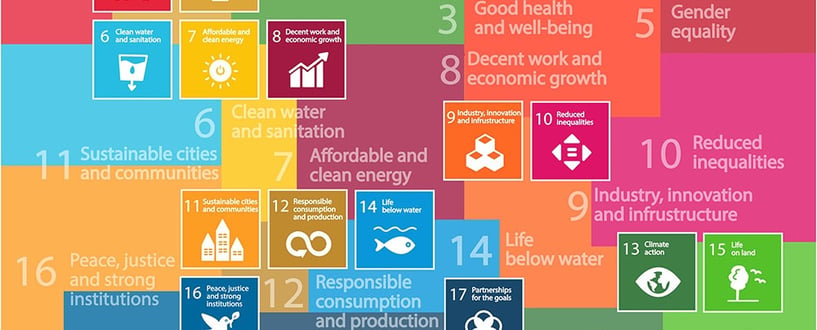

Contribution to follow SDGs Global Rules Book

SDGs - Sustainable Development Goals - is the human rights guide to address the development challenges faced in the world. SDGs has been developed by the Danish Institute for Human Rights consists of 17 ambitious goals among 169 targets, that focus on ending poverty, preserving the earth's environment, and ensuring everybody can experience peace and prosperity.

We can avoid infections from chemicals, air, water, and soil by adhering to ISO standards in production and prioritizing 5S. Employees who work in a safe and pollution-free workplace are more likely to stay on the job for a long period. Every year, we conduct a thorough examination of the average amount of fine dust within our plant, as well as the oxygen level in the office. We control air quality and waste in accordance with SDGs No.11 and safe working conditions in accordance with SDGs No.14. Allow us to accompany you in your quest to create a more peaceful, joyful, and clean planet.

- Category:

- General Topics

- Keyword:

- SDGs

- Calorized Lance Pipe