Since open tapping is a risky activity that might result in accidents in the lower parts of the copper smelter and ferrometal smelting, it is important to utilize safety/security materials. Open tapping in copper refining is commonly done using black pipes, and the issue is that if low-quality black tubing is used without recognizing it, there is a possibility of oil on the surface of the steel pipe, which may easily catch fire. Black pipes are utilized for open tap, which is somewhat less expensive but runs the risk of oxygen leaking from welds, in order to decrease expenses in the ferrometal refining process.

Since open tapping is a risky activity that might result in accidents in the lower parts of the copper smelter and ferrometal smelting, it is important to utilize safety/security materials. Open tapping in copper refining is commonly done using black pipes, and the issue is that if low-quality black tubing is used without recognizing it, there is a possibility of oil on the surface of the steel pipe, which may easily catch fire. Black pipes are utilized for open tap, which is somewhat less expensive but runs the risk of oxygen leaking from welds, in order to decrease expenses in the ferrometal refining process.

In this blog, we are going to introduce that by using Daiwa Lance's high-quality SC lance pipe, it is possible to both prevent hazards and improve efficiency in the copper smelter and ferroalloy smelter.

Copper Smelter and Ferroalloy Smelter

Copper smelting plants separate elemental copper from copper concentrates through numerous sulfide oxidizing processes. Primary copper smelting is the process of using pyrometallurgical techniques to refine copper sulfide ore concentrate from mined ore to create anode-grade copper.

Ferroalloy Smelter: Ferro-alloys can be created using either metal thermic reduction with other metals or carbon combined with a suitable smelting process. More often, ferroalloys are generated by carbothermic processes, including the reduction of oxides with carbon (as coke) in the presence of iron. Adding certain elements to molten iron results in the creation of certain ferroalloys. Many ferroalloys may also be produced using direct reduction techniques.

![]()

RELATED POST

Daiwa SC Lance Pipe Struture and Usages

Daiwa SC Lance is a mild steel pipe that generates a high temperature of over 3,000°C by burning itself and melts solidified steel and slag on equipment.

Usages of SC Lance pipes:

- Slag on the wall of the ingot case.

- Pig iron at the iron notch of a blast furnace.

- Slag in the ladle.

- Steel-slag mixture at slag notch and iron notch of a blast furnace.

Advantages of Daiwa SC Lance Pipe

Daiwa SC Lance is a mild steel pipe that is recommended to use in Copper Smelter and Ferroalloy Smelter due to various advantages:

・Welding: Daiwa SC Lance pipe is a high-quality mild steel pipe made from carefully selected raw materials, welded using high-frequency welding machines, and rechecked for welding leaks using electromagnetic inspection equipment, enabling us to provide reliable, high-quality mild steel pipes.

・Surface with no oil: opening tap holes are free of oil, grease, and other contaminants on the surface so which bring safety during the operating process.

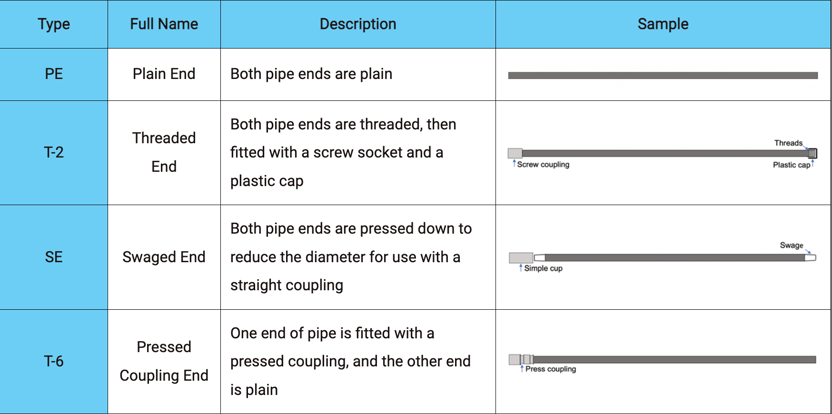

・Connections: Daiwa SC Lance is carefully designed and connected pipe to pipe to minimize Air leakage by various types of connection.

Conclusion

Daiwa SC Lance pipes are utilized for open tap, which is somewhat less expensive but runs the risk of oxygen leaking from welds, in order to decrease expenses in the ferrometal refining process.

If you wish to know more about our Daiwa SC Lance pipe possible to both prevent hazards and improve efficiency in the copper smelter and ferroalloy smelter, please contact our dynamic team to support you during your journey.

- Category:

- Daiwa Lance Products