The engineers and procurement personnel in the blast furnace should have sufficient knowledge of the purpose of the oxygen lance pipe suitable for each steelmaking process. The problem is that customers may not know the appropriate size of the oxygen lance pipe for the steel-making process of the blast furnace for safety, security, and health. By introducing the appropriate type and use of the oxygen lance pipes in the blast furnace, it is possible to clarify what the customer is wondering about.

In this blog, we are going to introduce by explaining appropriate oxygen lance pipes through the processes from pig iron to steel making in a blast furnace, it is possible to understand the characteristics of each oxygen lance pipe and utilize it flexibly.

First Application: Opening Tap Hole

During the steel production by Blast Furnace steel mills, the initial application is to use lance pipes to open the tap hole so that the production process will get enough flow of the melted iron. Taphole is situated at the bottom of the furnace and needs to open the hole periodically to take out the molten iron and slag.

- With this purpose, most manufacturers tend to choose Daiwa SC Lance pipes for opening the tap hole of the Blast Furnace. Daiwa SC Lance (SC) is a mild steel oxygen lance pipe made with HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, there is no oil, and no grease on the pipe.

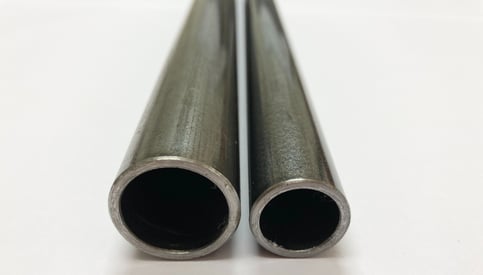

The size of the SC lance pipes for opening the taphole from OD13.8 mm to OD17.3 mm

Photo of Daiwa SC Lance Pipes in Various Sizes

- Besides that, some customers prefer using Thermic Lance with some specific sizes depending on their usage requirements and the size of the smelter. Daiwa Thermic Lance (TL) is a steel pipe filled with wires or a mixture of wires and an inner pipe, when burning generates a powerful flame up to 4,000°C without noise and vibration to break up materials quickly. Generally, the metal tube contains steel wire that promotes combustion. Thermic lances with sizes from OD 12.9mm (for small smelters) size to OD 27.2mm (for bigger smelters) are mainly purchased.

RELATED POST

Second Application: Cleaning Ladle Furnace

The ladle furnace separates the steel-melted activities from the treatments and refinery processes. The created molten steel is placed into the ladle, which acts as a furnace for metalworking activities at the processing facilities. When the leftover liquid is cool down, it is needed to clean the ladle furnace after processing.

Photo of Ladle Furnace Processing

The second application is that steel producers use the oxygen lance pipes of with various sizes from OD 8mm to OD 21.7mm.

Photo of Daiwa SC Lance Pipes in Sizes OD 21mm and OD 8mm

Final Application: Removing Slags

The accumulation of solidified slag trapped in mechanical equipment such as ladle cars or tundish nozzles in continuous casting equipment after the ironmaking process comes to an end can deteriorate operating performance over time.

- For that reason, in order to use this kind of slag removal, we need a material that can generate a higher temperature than the melting point of slag to melt it down and remove it. In this case, a thermic lance can be a choice for your consideration.

Daiwa Thermic Lance (TL) can produce a super high heat rate of up to 4,000℃ with

Fe + O2 → Fe2O3 + Heat reaction. The pipe transports solid oxygen from an air compressor and controller. A high heat generator, such as acetylene torches, is used to light the pipe's terminal. The pipes produce huge heat and a molten slag of oxidized iron and other elements that drifts and spills out like a massive fire candle.

.

.

Photo of Using Oxygen Lance Pipes for Removing Slags

- After pouring out liquid steel, the workers will use SC Lance pipe to clean stuck metal inside the converter after a long time using. The SC Lance pipe is called to be used over here once again for the cleaning furnace purpose. Daiwa SC Lance (SC) generates a high temperature of over 3,000℃ by blowing oxygen and melting solidified steel, and slag on equipment. The pipe can be used to remove slag on the wall of the ingot case, pig iron at the iron notch of the blast furnace; clean slag in ladle and steel-slag mixture at the slag notch and iron notch of a Blast Furnace, and cut steel scraps, such as size OD 21.4mm to OD 27.2mm.

Conclusion

By using Daiwa Lance pipes, there are also other various impacts that could support and bring to the whole steel production process. We apply various types of oxygen lance pipes that can enhance the performance of steel production by Blast Furnaces steel mills.

If you wish to know more about the suitable oxygen lance pipe, feel free to contact our dynamic team to support you during your journey.

- Category:

- General Topics