Electric arc furnace steel manufacturing is getting more popular due to the reduction of 3/4 amount carbon emitted to the environment. More and more steel makers do both enhancing the production performance and treating well to the environment. And so there is a trend to shift from Blast Furnace to Electric Arc Furnace widely. Each lance pipe used for the Electric Arc Furnace has a different purpose to enhance the performance of steel making process. However, there are some customers who still have concerns about what kind of lance pipe is appropriate for the steel-making process in an electric arc furnace, or what kind of lance pipe is appropriate for taphole drilling and ladle furnace cleaning. Therefore, it is optimal that electric furnace steelmakers should understand that there are appropriate lance pipes available for each process.

In this blog, we are going to introduce the general processes that lance pipes required for each process in electric arc furnace steelmaking, so that customers can definitely optimize the production by enhancing performance and cost saving.

First Process: Cutting Large Scraps

There are lots of processes in steel production by Electric Furnace including Electric Arc Furnaces. Initially, the first process in Electric Arc Furnace is to cut large size scraps as material preparation then put scraps in the Electric Arc Furnace. With this purpose, customers look for the oxygen lance pipe that are to be used for fusing the metals and so on. Therefore, Thermic Lance is one optimal option since the principle is that harness the oxidation heat of high temperature by providing the pressurized oxygen inside an ignited steel tube.

.png?width=1000&name=Thermic%20Lance%20Experiments%20(Steel%20Bar%20Cutting).png)

Photo of Daiwa TH Lance Pipes Cutting a Thick and Hard Steel Bar for Performance Testing

Daiwa Thermic Lance (TL) is a steel pipe filled with wires or a mixture of wires and an inner pipe, when burning generates a powerful flame up to 4,000°C without noise and vibration to break up materials quickly. Generally, the metal tube contains steel wire that promotes combustion.

Photo of Daiwa TH Lance Pipes

RELATED POST

Second Process: Injection to Electric Arc Furnace

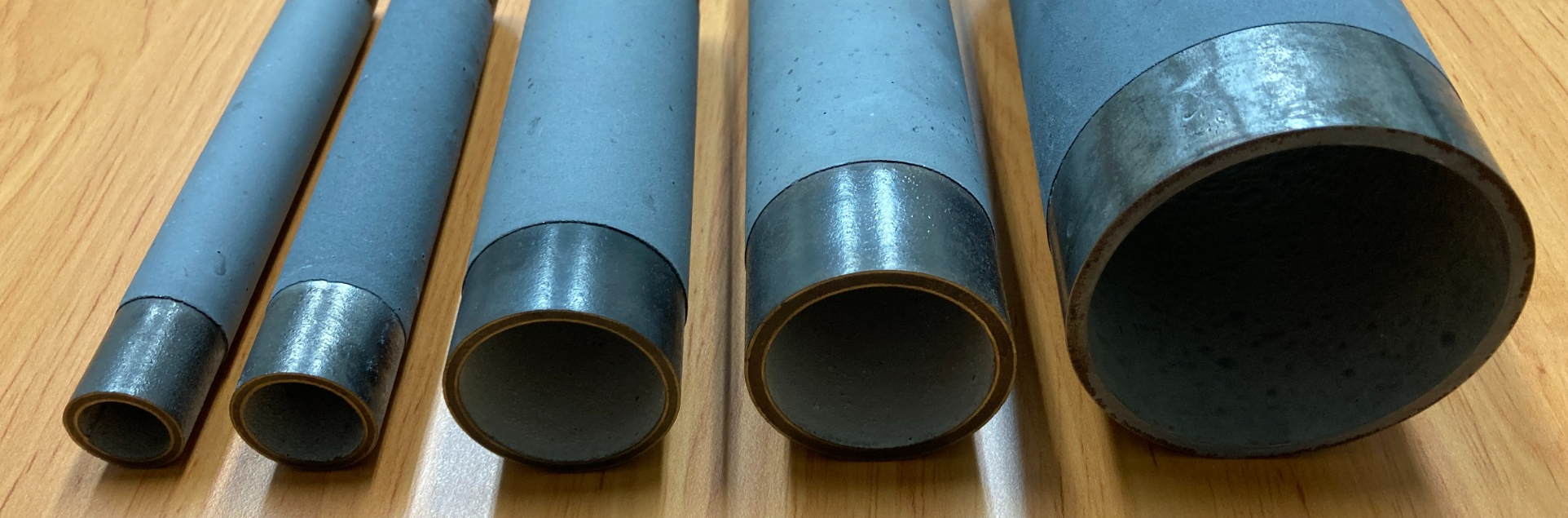

The lance pipes used for blowing oxygen, carbon and other materials into electric furnaces must be tough and resistant to heat and oxidation. And so the usage of Calorized lance pipes can reduce the number of lance pipes used, leading to cost savings and safe operations.

Daiwa CA Lance (CA) lasts 3 to 10 times * longer than mild steel lances and is used not only for the melting and refining of steel by blowing oxygen gas, but also used for the injection of carbon, lime, and/or other additives.

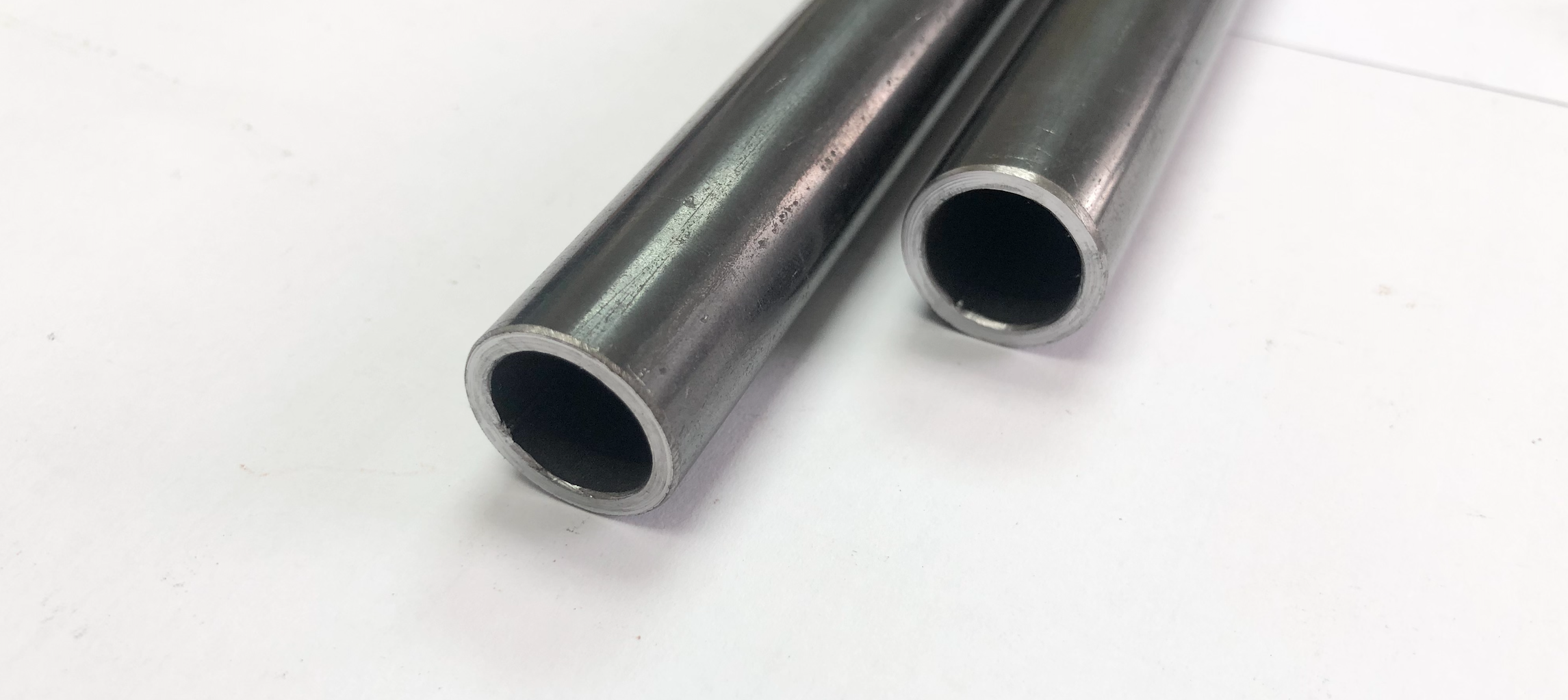

Photo of Daiwa CA Lance Pipes with Various Sizes

Final Process: Opening Tap Hole and Cleaning Furnace

The next process of steel production is to open the tap hole so that the production process will get enough flow of the melted iron. With this purpose, most of manufacturers tend to choose Daiwa SC Lance pipes.

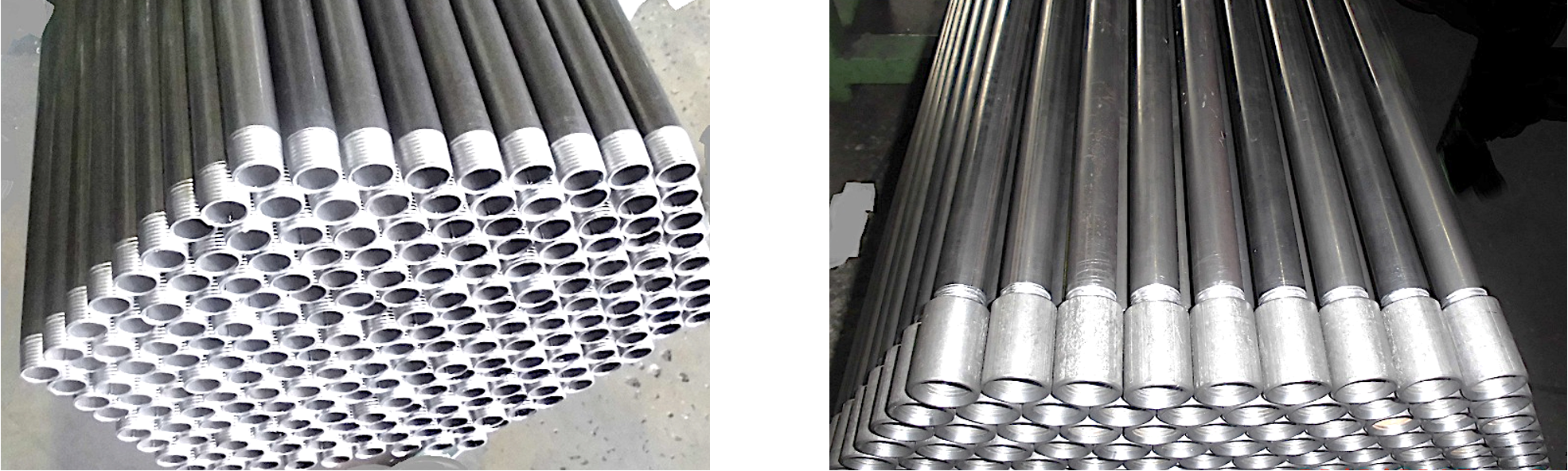

Photo of Daiwa SC Lance Pipes for Tap Hole Opening

Daiwa SC Lance (SC) is a mild steel oxygen lance pipe made with HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, there is no oil, and no grease on the pipe.

Photo of Daiwa SC Lance Pipes

Photo of Daiwa SC Lance Pipes in Bundle by Packing

Conclusion

By using Daiwa Lance pipes, there are also other various impacts that could support and bring to the whole steel production process. The time it takes to smelt steel is reduced, which helps to reduce fuel, oil, and gas, which are the main fuels used in steel production. The heating time of the Electric furnace count as tap-to-tap time, measure the minutes take our produced pig iron from the tap hole of the furnace to the next takeout.

If you wish to know more about the suitable oxygen lance pipe for melting down the trash, feel free to contact our dynamic team to support you during your journey.

- Category:

- General Topics