In this informative blog post, we will provide valuable insights into the essential lance pipe processes involved in electric arc furnace steelmaking. By understanding these processes, customers can effectively optimize their production, improving performance and achieving cost savings.

Initial Step: Efficiently Cutting Large Scraps

The initial step in the steel production process using an Electric Arc Furnace involves cutting large-sized scraps as part of the material preparation. These scraps are then placed in the furnace for further processing. During this stage, customers often seek out oxygen lance pipes that are capable of effectively fusing the metals. One excellent option that fulfills this requirement is the Thermic Lance. This lance pipe operates on the principle of harnessing the high-temperature oxidation heat by supplying pressurized oxygen inside an ignited steel tube.

.png?width=392&height=216&name=Thermic%20Lance%20Experiments%20(Steel%20Bar%20Cutting).png)

Photo of Daiwa TH Lance Pipes Cutting a Thick and Hard Steel Bar for Performance Testing

Daiwa Thermic Lance (TL) is a remarkable steel pipe that is packed with wires or a combination of wires and an inner pipe. When ignited, it produces an incredibly powerful flame that can reach temperatures of up to 4,000°C. This intense heat is generated without any noise or vibration, allowing the Thermic Lance to efficiently break up materials with ease. Typically, the metal tube of the Thermic Lance contains steel wire, which aids in the combustion process.

Photo of Daiwa TH Lance Pipes

Next Step: Injecting into the Electric Arc Furnace

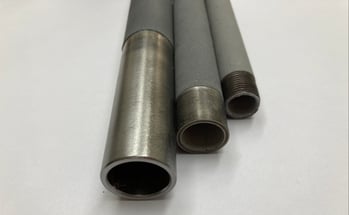

To effectively inject oxygen, carbon, and other materials into electric furnaces, it is essential to use durable lance pipes that can withstand high temperatures and resist oxidation. By utilizing Calorized lance pipes, the number of lance pipes required can be minimized, resulting in cost savings and safer operations.

Daiwa CA Lance (CA) can boast an exceptional lifespan that is 3 to 10 times longer than that of mild steel lances. These robust lance pipes serve multiple purposes, not only facilitating the melting and refining of steel by oxygen gas injection but also enabling the injection of carbon, lime, and other additives into the electric arc furnace.

Photo of Daiwa CA Lance Pipes with Various Sizes

Final Process: Opening Tap Hole and Cleaning Furnace

The next process of steel production is to open the tap hole so that the production process will get enough flow of the melted iron. With this purpose, most manufacturers tend to choose Daiwa SC Lance pipes. After pouring out liquid steel, the workers will use SC Lance pipe to clean stuck metal inside the converter after a long time using. The SC Lance pipe is called to be used over here once again for the cleaning furnace purpose.

Daiwa SC Lance (SC) is a mild steel oxygen lance pipe made with HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, there is no oil, and no grease on the pipe. Daiwa SC Lance pipe generates a high temperature of over 3,000℃ by blowing oxygen and melting solidified steel, and slag on equipment. The pipe can be used to remove slag on the wall of the ingot case, pig iron at the iron notch of the blast furnace; clean slag in ladle and steel-slag mixture at the slag notch and iron notch of a Eletrci Arc Furnace, and cut steel scraps.

Photo of Daiwa SC Lance Pipes

Conclusion

By utilizing Daiwa Lance pipes, there are numerous additional benefits that contribute to the overall steel production process. One significant advantage is the reduction in smelting time, resulting in decreased consumption of fuel, oil, and gas, which are the primary energy sources in steel manufacturing. Additionally, the heating time of the Electric furnace, known as the tap-to-tap time, measures the minutes it takes to transport our produced pig iron from the furnace's tap hole to the subsequent takeout point.

If you wish to know more about the suitable oxygen lance pipe for melting down the trash, feel free to contact our dynamic team to support you during your journey.

- Category:

- General Topics