Drilling the Pin to Replace Parts of Large Shovels in Copper Mine

RELATED POST

Cutting Consumable Parts of Large Excavators

Excavator baskets are built from a variety of metals that provide hardness to make excavators last longer and hardly wear out. The materials are required depending on the part's capacity and production technique.

Excavator pins are often constructed of AISI 4130 or 4140 steel, which promotes corrosion resistance and toughness whereas molybdenum boosts surface hardness. The container sidewalls and forefront are often composed of AR360 and AR400 alloys which have been properly hardened to produce products with exceptional fracture toughness and strong tensile properties. The bucket shell is frequently manufactured of ASTM A572 Grade 50 (also known as A-572-50), a high-strength, low-alloy steel.

Due to the hardness of excavators, whenever users want to cut them into pieces for removing process, having applicable oxygen lance pipes with extremely strong heat would be the initial requirement. Many users choose to use Thermic Lance as the optimal option to enhance the performance of cutting those tough parts of excavators.

The correct angle to operate Thermic Lance is also a crucial part of enhancing its performance of the Thermic Lance. We also support our customers with the full instruction of the "Step-by-step Guide to Operate Thermic Lance with Safety and Effectiveness", here.

Taphole Drilling in Copper Smelting Process

The taphole, which is placed just above the bottom of the furnace's hearth, is used to extract slag and molten steel from the furnaces. Furnace tapped is the technique used to remove slag and heat sources from the heart of a furnace. For the purpose of taphole drilling, we recommend our customers use the oxygen lance pipe named SC Lance which can suit the required performance and cost savings.

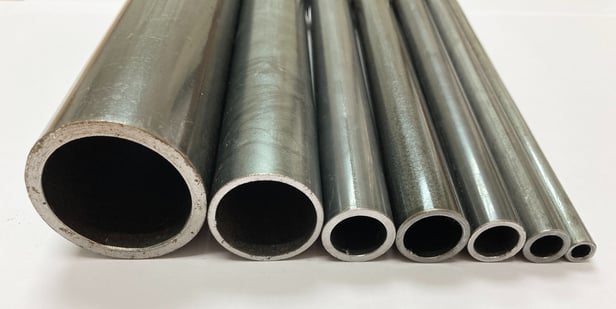

DAIWA SC LANCE is a mild steel oxygen lance pipe made with HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, there is no oil, and no grease on the pipe. DAIWA SC LANCE generates a high temperature of over 3,000℃ by blowing oxygen and melting solidified steel, and slag on equipment.

Conclusion

By using Daiwa Lance pipes, there are also other various impacts that could support and bring to the whole steel production process. Beside steel production process, Daiwa Lance also can apply various types of oxygen lance pipes that can use for other purposes.

If you wish to know more about the suitable oxygen lance pipe, feel free to contact our dynamic team to support you during your journey.

- Category:

- General Topics