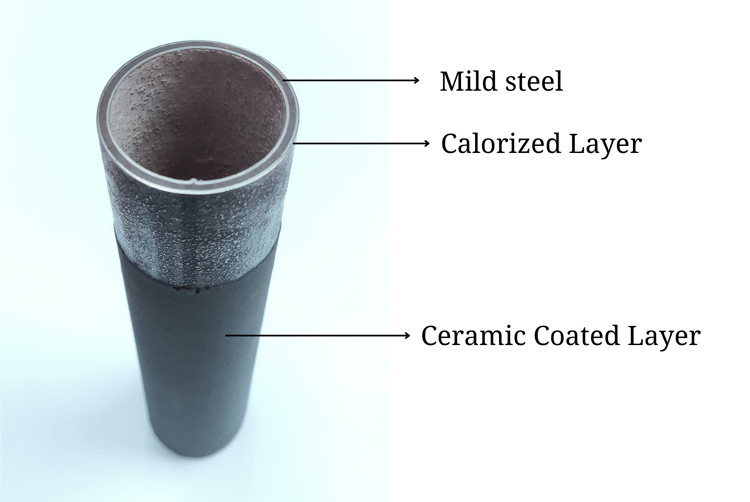

Calorized Layer

Calorized Layers are created by diffusing aluminum into mild steel pipes at temperatures exceeding 1000°C. This process forms heat-resistant aluminum-iron alloys on both the inner and outer surfaces, enhancing the pipes' high-temperature resistance.

The process of applying a calorized layer involves heating the metal surface to a high temperature and then diffusing the aluminum-iron alloy onto it. As the aluminum-iron alloy comes into contact with the hot metal surface, it melts and fuses with the surface, creating an aluminum oxide (alumina) film over the surface and protects mid steel pipes against severe oxidation.