Steel pipe is frequently employed in steel mills and on construction sites, because of its modest size and shown capacity to cut through thick and substantial chunks of scrap steel. However, this product's features go beyond only its potent cutting ability. Many people often think about the ideal lance pipe to use for each different function in order to get the greatest performance and improve cost-saving. And one way to solve their worries would be to have a firm grasp of the melting point before making a purchase choice.

Let's look at a various situations in this blog post to know various melting points of metal and how we suggest to type of Thermic Lance pipe for difference usage purposes.

Main Types of Metals

There are many ways to classify types of metals but in this article, we divide metals into 2 main types: ferrous metals and non-ferrous metals.

Ferrous metals refer to any metal that is primarily comprised of iron and have magnetic properties like steel or cast iron.

Nearly 90% of the world's annual production is made up of ferrous metals, which are essential for building homes and fabricating industrial products.

Non-ferrous metals, on the other hand, refer to metals without the composition of iron like aluminum, copper, tin, lead, or zinc.

Non-ferrous metals are frequently utilized extensively in the automotive, aerospace, or high-end luxury furniture industries where cost is not a major concern for end-users due to its lightweight characteristics, scarcity, and expense.

RELATED POST

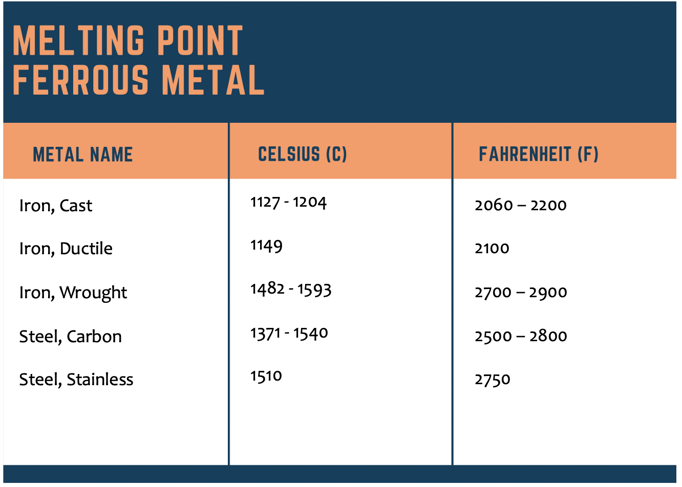

Melting Point of Ferrous Metals

The two most crucial elements in the process of recycling steel waste into new goods are cast iron and steel. Their melting points are often greater than 1,000oC. (1,832oF). For engineers, dissolving metals into solutions from the original form during the smelting or scrap cutting process is physically exhausting at this high temperature. Because heat is required to melt the metals, the greater the temperature, the more heat is required.

Take a quick look at the table below for the actual melting point of ferrous metals.

(Table of Melting Point for Ferrous Metals in Cesius and Fahrenheit scale)

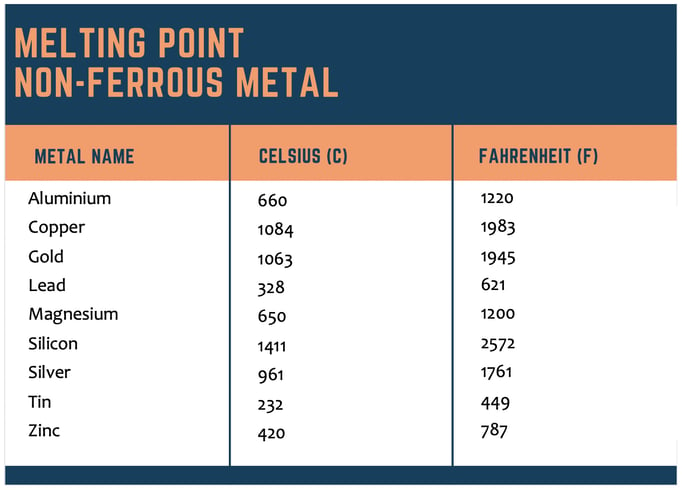

Melting Point of Non-ferrous Metals

The same procedure may be used to reduce non-ferrous metals' melting points in order to improve production efficiency. To reduce the rich components that each non-ferrous metal has, for instance, we may add lead or tin to tin instead of carbon. It is clear from the table below that non-ferrous metals' melting points can range from higher to lower than 1,000oC (1,832oF), which gives us the idea that ferrous metals' melting points are generally greater than those of non-ferrous metals.

The melting point of ferrous metals can occasionally be greater than that of non-ferrous metals, and vice versa. The table below only lists the most common non-ferrous metals; it does not list all of them.

(Table of Melting Point for Non-ferrous Metals in Cesius and Fahrenheit scale)

Have you ever consider which melting points and method could be considered to use during production process? Let's us show you the lance pipe that could support and solve your concerns.

Thermic Lance for Steel Production

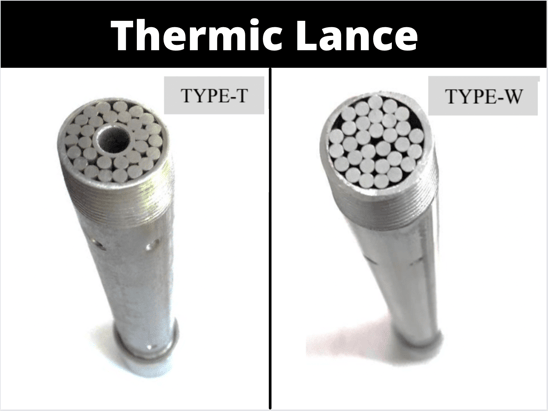

Daiwa Thermic Lance (TL) is a steel pipe filled with inner tube and wires and creates super high temperature and powerful flame by burning itself and produces high heat. Thermic Lance can produce super high heat rate up to 4,000℃.

Type T is more focusing on easy operation and usage by non-stop fire. It can keep oxygen flow continuously and enhance the continuous operation and this helps suitable for steel scrap cutting. Type-T mostly is suitable for cutting steel piles, large scrap objects, and solidified spillages of metals.

Type-W is used for removing solid metals, slag stuck, cleaning ladle nozzle and tundish nozzle in casting. Type W can create more energy than Type T and is used to cut stainless steel heavy scrap since the process requires more energy from a wider flame at a higher temperature.

If you wish to know more about Melting points and which Thermic Lance could be suitable with your purpose, contact our dynamic team to get more precise information. We will support you during your production journey with the best performance.

- Category:

- General Topics