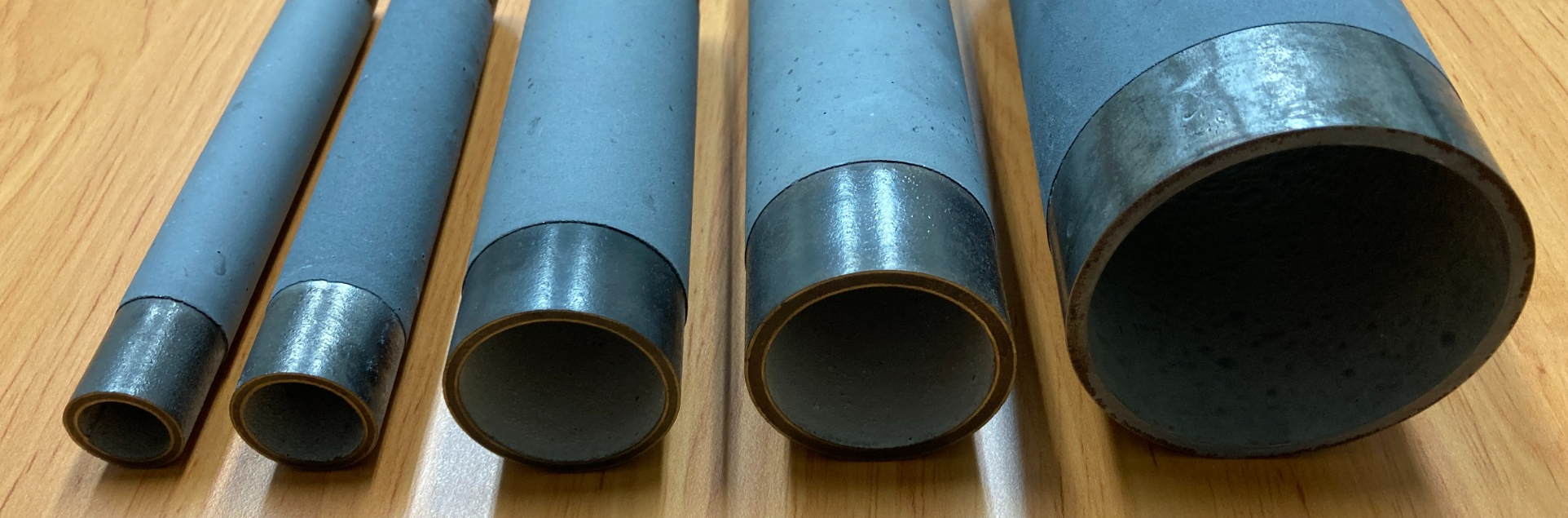

Calorized Lance Pipe

Calorized lance pipe is a type of lance pipe used to inject oxygen and carbon or other additives in the steelmaking process. In order to reach a high level of heat and oxidation resistance, calorized lance pipe will need to undergo a calorizing process.

The calorizing process diffuses aluminum onto the surface of a lance pipe and heats it to 1,000°C to form a heat-resistant aluminum-iron alloy (calorized layer) on the surface.

When exposed to high temperatures, a heat-resistant aluminum oxide (alumina) coating is formed on the surface of the calorized layer, inhibiting severe oxidation of the lance pipe.

Calorized lance pipes have a great contribution to longer life, cost savings, and safer operations in EAF as well as many other common furnaces in the steelmaking industry.