One of the various pipes used in the steel-making process is mild steel pipe. Daiwa Lance has created Daiwa SC lance pipe with several unique characteristics that may be utilized for various applications in the steel manufacturing process according to this international requirement. It is feasible to give you sufficient bits of knowledge in this article by highlighting Daiwa SC Lance's positive traits and focusing on value-added points, enabling you to contact us with confidence later.

Daiwa SC Pipe: What is it?

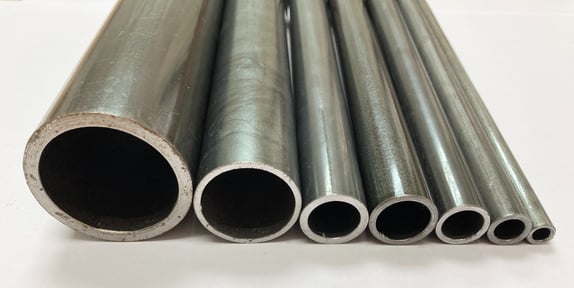

Steel with a low percentage of carbon (less than 0.25%) is used to make mild steel (MS) pipes. The pipes are easy to operate since they contain less carbon and do not harden. Since mild steel is used to manufacture MS Pipes, it is simple to join and curve them into a range of diameters and forms for pipelining and tube applications.

A high-frequency welding machine is used to produce Daiwa SC Lance mild steel pipes, which are composed of hot-rolled steel sheets without grease- and oil-covered pipes. By blowing oxygen and melting steel that has hardened and slag on machinery, Daiwa SC Lance produces high temperatures of over 3,000°C.

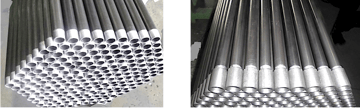

Photo of Daiwa SC lance Pipes

Application of Daiwa SC Lance Pipe

- Opening Tap Hole

Lance pipes are initially used to open the tap hole during the manufacturing of steel by blast furnace steel mills in order to ensure that the flow of molten iron into the process is sufficient. To remove the molten iron and slag, the taphole at the bottom of the furnace must be periodically opened.

- Removing Slag:

- Cleaning Purpose:

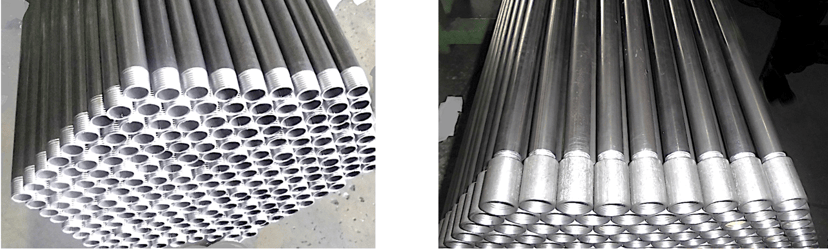

Connection Types of Daiwa SC Lance Pipe

- Plain ends -- Some customers prefer to use plain ends of SC lance pipe without any connection when one piece is enough to complete the job.

- Thread & socket: it is easy to connect 2 pipes no need to waste half-used pipe. For this type, we use a wrench for tightening while connecting the pipe.

- Press Coupling: it's an easy connection type, by just hitting pipes and coupling them together to the wall or floor a coup of times then connecting.

* Special Chamfering: Besides the normal Plain End type, we also can prepare this special Chamfering due to customers' requirements and it is easy to insert a holder in this case.

Conclusion

For more details, please feel free to consult with our sales department or sales agent. We will always do our best effort to serve you.

- Category:

- Daiwa Lance Products

- Keyword:

- information about sc lance

%20size%20CTA%20theo%20Nh%E1%BA%ADt%20%20(1)-1.png?height=510&width=1200)