In order to reduce the significant amount of irons (Fe) inadvertently dissolved into molten silicon (Si) during the purification, silicon metal manufacturers have increasingly turned to Aluminum Lance Pipes as an alternative to oxygen lance pipes. These Aluminum Lance Pipes serve the same purpose as oxygen lance pipes without introducing any unnecessary iron content that could potentially impact the grade of silicon during the smelting process. However, the questions still remain: do Aluminum Lance Pipes' heat-resistance properties sufficient to withstand the intense high heat environment of molten silicon in Submerged EAF? How can we ensure the straightness and hardness of Aluminum Lance Pipes during the manufacturing process? Find the answers to these questions and more in our blog posts here.

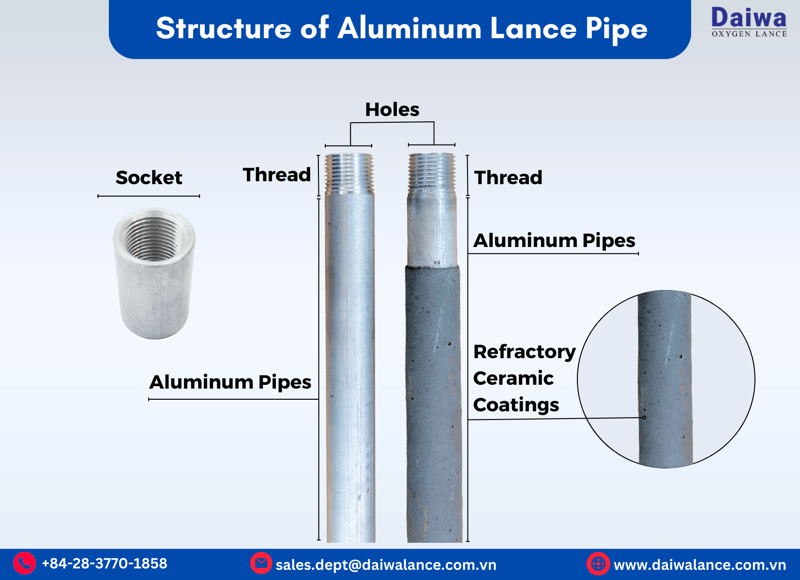

Structural Elements of Aluminum Lance Pipes

Aluminum Lance Pipes stand out as a variant of oxygen lance pipes with aluminum as primary materials, featuring a round and hollow pipe structure that enables efficient and precise delivery of oxygen during the production process of silicon metal. Let's take a closer look at the components below to get a comprehensive understanding of the structure of Aluminum Lance Pipes.

(Structural Elements of Aluminum Lance Pipes)

Aluminum Pipes

Unlike conventional oxygen lance pipes, Aluminum Lance Pipes are constructed using aluminum as primary materials. The choice of aluminum as the main material for these lance pipes is strategic. By utilizing Aluminum Lance Pipes to blow oxygen into molten silicon, the chances of iron content being mixed into molten silicon are significantly reduced.

Refractory Ceramic Coatings

To further enhance the heat resistance of Aluminum Lance Pipe, its surface is coated with a thick layer of refractory ceramic coatings aiding in preventing the heat from penetrating the aluminum pipe and maintaining its structural stability. With the melting point above 2,000oC, ceramic coatings also serve as a protective barrier, increasing the lance pipes' ability to withstand the extremely high temperatures as well as prevent direct contact which causes unnecessary chemical reactions between molten silicon and aluminum pipes.

Holes

The holes of Aluminum Lance Pipes are strategically designed along the length of the lance pipes to ensure a smooth and uninterrupted flow of oxygen into Submerged EAF. The diameter and spacing of the holes are carefully calculated to ensure an even distribution of oxygen into molten silicon, allowing for precise temperature control and reduction of iron content.

Thread and Socket

Thread and socket play a vital role in connecting two different lance pipes, ensuring a seamless flow of oxygen and minimizing waste during the manufacturing process. By securely fastening one lance pipe to another using thread and socket, manufacturers can ensure a tight and leak-free connection. This eliminates any potential gaps or openings that could result in oxygen leakage and decrease the efficiency of the lance pipes.

RELATED POST

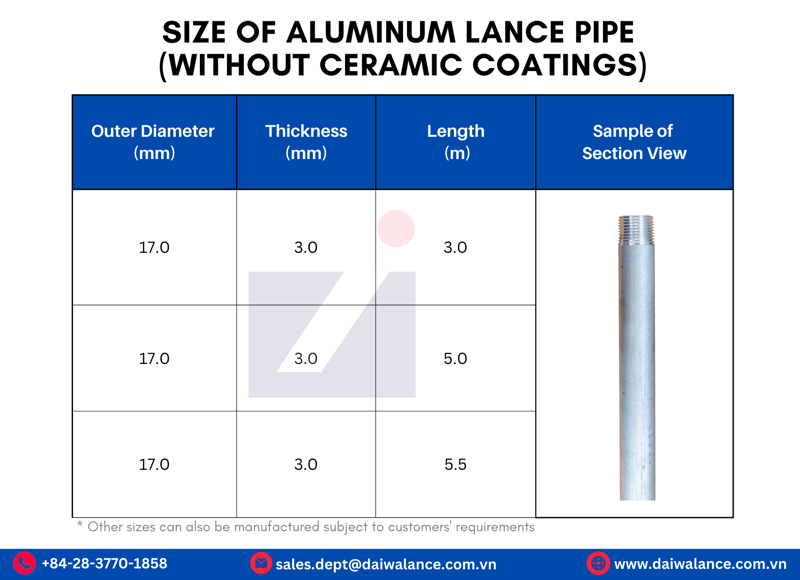

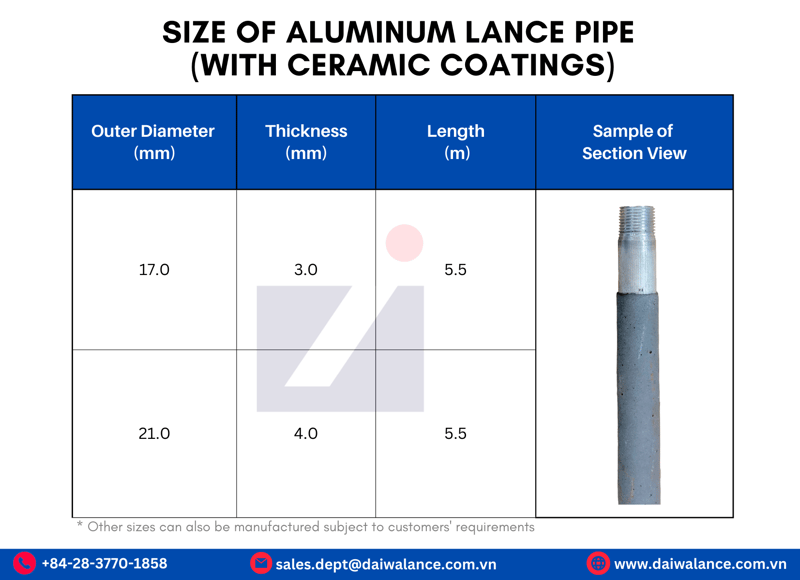

Size of Aluminum Lance Pipes

Corresponding to the Aluminum Lance Pipe structures described above, Daiwa Lance currently provides the following sizes:

Without Ceramic Coatings

(Size of Aluminum Lance Pipes without Ceramic Coatings)

With Ceramic Coatings

(Size of Aluminum Lance Pipes with Ceramic Coatings)

These sizes have been carefully selected to cater to various production needs in the manufacturing of silicon metal. However, at Daiwa Lance, we understand that each production process may have unique requirements. Therefore, we also offer the option for custom sizes to ensure the perfect fit for your specific needs.

If the current sizes do not meet your requirements, we encourage you to contact us. Our team of experts will work closely with you to understand your needs and provide you with a custom size solution. We are committed to delivering high-quality products that meet your exact specifications.

Conclusion

At Daiwa Lance, we take pride in our ability to provide exceptional products and services to our customers. Our Aluminum Lance Pipes have been designed and manufactured with precision, ensuring their durability and effectiveness in the intense high-heat environment of molten silicon in Submerged EAF. We prioritize the quality and performance of our products to ensure the success of your silicon metal production.

Stay tuned for our upcoming blog posts, where we will delve deeper into the advantages and features of Daiwa Aluminum Lance Pipes. We will provide detailed information on its properties and highlight the superior qualities that set our Aluminum Lance Pipes apart from ordinary ones in the market. Our goal is to provide you with the knowledge and insights you need to make informed decisions for your silicon metal production.

- Category:

- Daiwa Lance Products