Frequently, there are concerns of users that, “Mild steel pipes are good enough to blow oxygen into the furnace, why should we use Calorized Lance Pipe?” or “How effective are Calorized Lance Pipes in comparison with mild steel pipes?”

In this blog, we're going to share some of the most distinguishing features of these two particular oxygen-blowing equipment so that you can answer the above questions with certainty.

Mild Steel Pipe

Mild steel pipes are made of steel with low carbon content. Because of their low carbon content, the pipes do not harden and are simple to use. Due to its mild steel construction, Mild steel pipes may easily be welded and shaped into a variety of shapes and sizes for use in pipelining and tube applications. This sort is frequently used in a range of industrial and engineering applications, as well as for lancing needs in the production of steel.

Photo of Mild Steel oxygen lance pipe

Applications of Mild Steel oxygen lance pipe are various including removal of slag on the wall of the ingot case or pig iron at the iron notch of the blast furnace; Cleaning slag in ladle furnace or Steel-slag mixture at slag notch and iron notch of the blast furnace; Cutting steel scap.

All these purposes are applied to use in the steel manufacturing process, however the lifespan of Mild Steel oxygen lance pipe lasts shortly due to the low carbon component and no hardening by any technology. This would bring inconvenience to end users due to time lost and safety risks due to changing pipes in front of the furnace.

RELATED POST

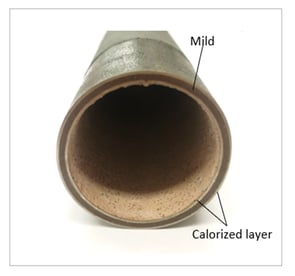

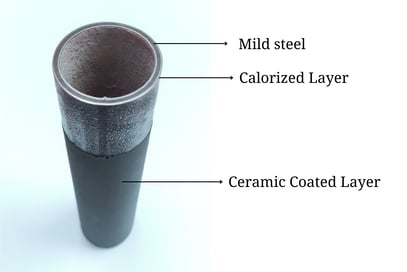

Calorized Lance Pipe

Photo of Daiwa Calorized Lance pipe structure

Applications of Daiwa Calorized Lance pipe:

- Cutting steel scrap, melting and refining steel at electric arc furnace.

- Injection of carbon, lime powder and/or other additives for adjusting grades of carbon steel or special steel.

- Removing slag inside oxygen converter.

- Other uses which require strong resistance against heat, oxidation, sulfuration, vanadium attack, etc.

Photo of operating Oxygen Lance pipe in Steel Production

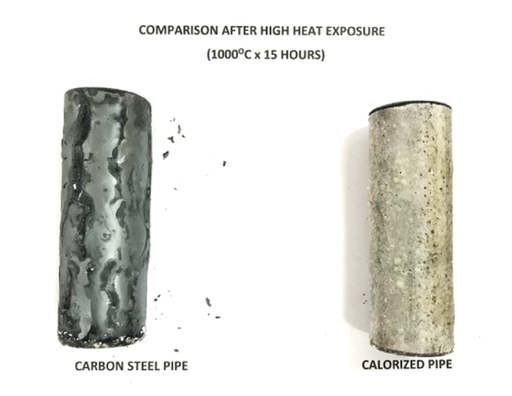

Photo of Mild Steel Pipe and Calorized Lance Pipe under High Heat Temporature

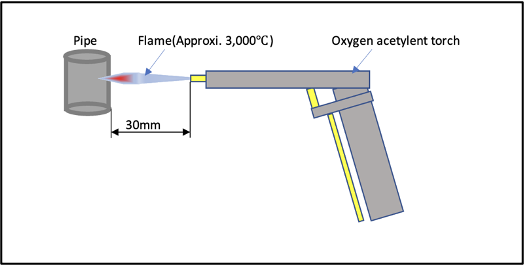

We show one of the proofs of how Daiwa Calorized Lance pipe is strong for high heat compared with a carbon steel pipe. We use acetylene touch and compare the time of making a hole between the carbon steel pipe and DAIWA CA LANCE PIPE. In this experiment, the Mild Steel pipe takes 20 seconds to have a hole. Daiwa Calorized Lance pipe could last 151 seconds to have a hole in it which has lifespan 7.5 times longer under high heat compared to Mild Steel oxygen lance pipe.

Photo of experiment

Conclusion

Depending on each application and usage purposes, end-users have many options to use steel pipes to enhance performance. Where mild steel pipes are still being used for oxygen blowing, it would be ideal for the steel industry to provide a persuasive case for buying so that end users may feel at ease switching from mild steel pipes to Calorized lance pipes not only for cost savings but also for performance and safety enhancing.

If you wish to know more about our solution for oxygen lance pipe for steel production process, especially for Electric Furnace, please contact our dynamic team to support you during your journey.

- Category:

- Daiwa Lance Products