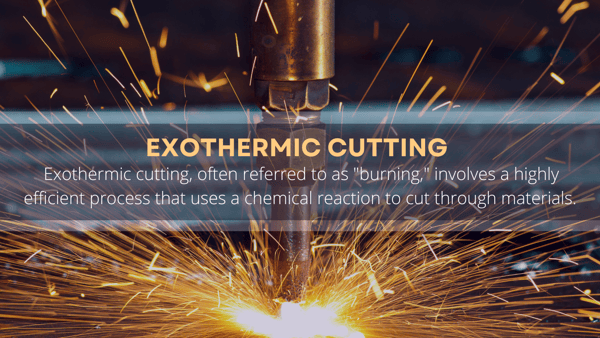

Exothermic Cutting

Exothermic cutting, often referred to as burning, involves a highly efficient process that uses a chemical reaction to cut through materials. It is achieved by igniting a mixture of fuel and oxygen in a cutting lance, resulting in extreme temperatures exceeding 6,000 degrees Fahrenheit (3,315 degrees Celsius). The intense heat generated melts or vaporizes the material, creating a clean and precise cut.

Exothermic cutting finds applications in a wide array of industries, making it a versatile choice for various scenarios:

- Demolition and Construction: In the construction and demolition industry, exothermic cutting is employed to remove and modify concrete structures, steel girders, and other heavy materials quickly and precisely.

- Ship Breaking: Exothermic cutting plays a vital role in disassembling ships, allowing for the efficient recovery of valuable materials.

- Emergency Rescue: Firefighters and rescue teams use exothermic cutting to access disaster sites and rescue individuals trapped in wreckage.

- Industrial Maintenance: For the repair and maintenance of industrial equipment, exothermic cutting is used to remove damaged or worn components.

- Railroad Industry: The railroad sector utilizes exothermic cutting to maintain and modify rails and infrastructure.